![]()

By Dave McCracken

Under many circumstances, it is wise to first verify that a viable deposit exists on a property before a substantial investment is made into production equipment.

How to outfit a suction dredging project, to a large degree, comes back to how you would answer the following questions:

1) What am I trying to accomplish; (sampling, production, or both)?

2) Where?

3) In what period of time?

3) In what period of time?

4) How much of a budget is available for acquisition of equipment and for operational start-up costs?

A gold (and/or gemstone) mining project basically should to be looked at in two separate steps: First you sample to locate a viable deposit. Then you launch into a production program to recover the gold or other valuable minerals from the deposit. Generally, the idea is to minimize investment into a particular mining property until a viable deposit has been located and verified.

Production-equipment is commonly larger and is more expensive to purchase and move around. The logistical infrastructure to support a production operation is usually more substantial and costly than what would normally be required to just go in somewhere for a short sampling program. . So generally-speaking, a production operation costs more to set up and involves more gear and supplies to move around and put into place. Therefore, under many circumstances, it is wise to first verify that a viable deposit exists on a property before a substantial investment is made into production equipment. The idea behind sampling is to minimize risk.

Prospecting Equipment & Supplies

The following video sequence will provide you with a visual demonstration of this very important point:

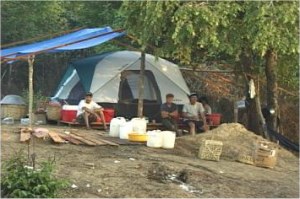

A typical camp to support a preliminary sampling operation usually would involve just the basic necessities.

The answers to “Where?” and “For how long?” also impact upon your decision about what kind of gear to buy. For example, if you are not tied to just one mining property, and you are prepared to launch a sampling program onto different properties until you find what you are looking for, then it would be a good idea to invest in good sampling equipment that is portable enough to move around the properties which are available to you. In this case, the capital expenditure is not tied to a single property, but rather into a portable sampling infrastructure that can be used for an extended period of time in many different places.

While sampling-gear is more portable, the smaller the size of a dredge, the less volume of streambed material it will process (in the same experienced hands), and the less-deep it will effectively excavate a sample into the streambed. Therefore, you trade-off productive effectiveness and the capability to make meaningful, deeper samples as you reduce dredge-size and gain in portability.

Two Pro-Mack 5-inch dredges were used to find rich deposits on this river in Cambodia, before a 10-inch production dredge was brought on line.

As an example of this, a 4-inch dredge can effectively sample down to around 4-feet deep in hard-packed streambed material). A 5-inch dredge can excavate about twice the volume of a 4-inch dredge down to around 5-feet of material. But the bulk of gear to move around is about twice as much.

A 6-inch dredge can excavate about twice the volume of a 5-inch dredge down to around 6-feet of hard-packed streambed. But the bulk of gear to move around is about twice as much.

An 8-inch dredge can excavate about twice the volume of a 6-inch dredge down to around 8-feet of material. But the bulk of gear to move around is about twice as much.

Here follows a video segment of a typical commercial dredge operating on the Klamath River in Northern California:

Ten-inch Pro-Mack dredge operating on New 49’er properties in Northern California.

A 10-inch dredge can excavate about twice the volume of an 8-inch dredge down to around 10-feet of material. But the bulk of gear to move around is about twice as much. By now, we are talking about a pretty substantial platform. But it still remains portable enough to place inside of an ocean shipping container, and can be towed around on wheels behind a small truck. For example, watch how this recovery platform for a 10-inch production dredge can be moved around by a normal-sized truck. This particular platform was built to ship overseas inside of an ocean shipping container:

These are just guidelines, because conditions change from one location to the next. It does not mean you cannot dredge deeper into the streambed using smaller-sized dredges. You can! But it generally does mean that the deeper you go beyond these guidelines, the less effectively your time will be invested. This is mostly a matter of over-sized rock management. All rocks that are larger than the intake-size of the dredge’s suction nozzle must be moved out of the way by hand. When dredging in an average hard-packed streambed, at the point where an experienced operator gets down through 5-feet of material using a 5-inch dredge, he has so many rocks to get out of the dredge hole that he is lucky to spend half his dredging-time operating the suction nozzle!

Bigger dredges get more accomplished primarily because they will suck up larger-sized rocks.

Under most circumstances, there are a proportionate greater number of smaller-sized rocks in a hard-packed streambed, than larger-sized rocks. So this is really a discussion about effective time-management. Since a larger dredge will suck up a larger rock, it means the operator will not have to move smaller-sized rocks from the excavation by hand. So he or she will spend his time moving even larger rocks out of his way, of which there are proportionally-fewer. This means he will get more done faster, and be able to dredge deeper into the material, before he reaches the point that there are just too many rocks to move out of the way.

Using a 5-inch dredge will mean having to move many, many more rocks by hand that would more-easily be sucked up the nozzle of a larger dredge.

This important reality cannot be overcome by positive thinking or an abundance of enthusiasm (as important as these are to have). We are talking here about the physical reality of how an excavation is accomplished. The size of the dredge-nozzle determines what size of rock can be sucked up (which is fast and easy), and what must be moved out of the hole by hand (which takes more time and effort).

The following video sequence demonstrates this very important point, and also explains why you must be very careful about projecting the true volume capability of different-sized dredges during feasibility planning:

By the way, when conditions allow for it and you want to increase the productive capacity of your equipment, you can also organize two or three separate teams to take shifts using the same production equipment. As demonstrated in the following video sequence, lights can even be set up to do a night shift:

So when deciding what to acquire for sampling or production equipment, it is necessary to balance the desire to get more productive activity accomplished (bigger dredge), with the necessity to remain portable (not so big that you cannot move it around to find what you are looking for). This must be decided on a case-by-case basis.

Here is my advice: Go as big as you are able to without forfeiting the portability that is required for your particular situation. I suggest these important decisions can only be wisely made after at least a preliminary evaluation of the project-area is completed.

Once you have proven-out your deposit(s) by sampling, you can feel more comfortable investing in production equipment and support-infrastructure to develop the project. In that case, bigger is not always better. Sometimes it is. A lot will depend upon the depth of water and streambed where you will be dredging. For example, a 10-inch dredge might not be as productive as a 6-inch dredge in a shallow-water and shallow-streambed area where a larger dredge cannot be floated around easily.

Another example is where shallow streambed material is made up largely of boulders that must be winched out of the way. In this case, some of your money might be better invested into a good mechanical or hydraulic winch, rather than a larger-sized dredge.

A well-done preliminary sampling program should result in a good production plan, based upon what type of equipment will be required to obtain optimum production under the conditions which exist where the gold deposit is located.

A well-done preliminary sampling program should result in a good production plan, based upon what type of equipment will be required to obtain optimum production under the conditions which exist where the gold deposit is located.

I am not going to discuss sampling, production or recovery systems here, because they have been covered in other articles. But since the type of equipment you should acquire is directly related to these subjects, I suggest it is a good idea to review that material very closely.

Some dredges are made to operate from the surface with the use of an automated cutter-head device at the nozzle. These are generally ineffective in hard-packed streambeds that are mostly made up of oversized rocks.

Some dredges are available with hydraulic-powered cutter-heads to help with the excavation. These are mechanical devices that help feed material evenly into the nozzle. They are most productive in doing channel-work in harbors or making navigation channels deeper or wider. Hard-packed streambeds which are made up mainly of oversized rocks and boulders will usually destroy a cutter-head device in short order.

Some dredges are available with hydraulic-powered cutter-heads to help with the excavation. These are mechanical devices that help feed material evenly into the nozzle. They are most productive in doing channel-work in harbors or making navigation channels deeper or wider. Hard-packed streambeds which are made up mainly of oversized rocks and boulders will usually destroy a cutter-head device in short order.

Here follows the normal steps in the development of a mining program:

1) Preliminary evaluation: This is where you take a hard look at the available information about a potential project. Then you go out and have a direct look at the specific location(s) and surrounding area. You are looking at the potential for commercial gold (and/or gemstone) deposits. You are also looking at what it would take to accomplish a preliminary sampling program, based upon all of the information and observation you can bring together. A preliminary evaluation will often result in a preliminary sampling plan.

2) Sampling Program: Depending upon what the objectives are, sometimes sampling is accomplished in several stages. Generally, the purpose of a sampling program is to locate and verify the existence of a commercial deposit that is valuable enough to justify a production operation. Sampling should work out the recovery method upon which the deposit may be developed efficiently. A sampling program can evolve into feasibility planning to develop a mineral deposit.

3) Production Operation: Is full or partial development of the deposit.

While there can be some overlap, equipment needs are usually different in each phase of a mining program.

While each project is different, during a preliminary evaluation, I personally always at least bring along a face mask (so I can have a look at the underwater environment where we would sample), a gold pan and classification screen, zip-lock sample bags and marker pen, map, GPS, camera equipment, local money in small denominations (to buy mineral samples from local miners), a dozen bright-colored ball-caps (gifts for local miners), a bottle or two of whiskey (gift for the village chief in non-Muslim communities), and the other basic things I will need to visit that particular environment.

A sampling program will basically require the same things as will be required in a full production operation, but usually on a smaller and more portable scale. Here follows a basic outfitting list:

Dredging Equipment:

Dredge

Boat (and motor?) and ores

Winching gear and rigging?

Pry-bars

Rope (floating)

Fuel containers

Complete set of tools needed to service the gear

Diving Equipment:

Face mask

Air reserve tank and fittings

Air line(s) & regulator(s)

Wet-suit?

Weight belt & weights

Protective foot ware (steel tips?)

Rubber work gloves (bring spares?)

Clean-up Gear:

Wash tubs

Classification screens

5-gallon buckets

Scraping tool and/or hand scoop

Final concentrating equipment?

Gold pans

Steel finishing pans

Magnet

Portable gas stove

Weight scale

Zip-lock sample bags and marker pen

Support Gear:

Vehicle-support?

Shelter

Cooking & eating utensils

Wash tub for kitchen

Cook stove

Toilet facilities?

Portable chairs & table

Medical kit

Waterproof bag(s)

Ear infection preventative

Maps, GPS and camera equipment

Electric generator?

Camp lights

Paper and pens

Communication equipment?

Flashlights & batteries

Knife

Firearm?

Supplies:

Drinking water and/or filters

Food supplies and containers

Fuel & motor-oil for all motors

Dish washing detergent

Chlorine for sanitizing cleaning water

Laundry wash tub and soap

Hand-wash soap

Tissue paper

Cook stove fuel or canisters

Duct tape

Nylon line (plenty)

Plastic trash bags

Zip-lock bags & plastic containers for food

Spare Parts (priority often depends upon how remote the project location is):

Tune-up replacement parts for all motors

Extra water pump seals and bearings

Extra compressor & alternator belts

Rebuild kit for air compressor

Extra air compressor?

Rebuild kits for dive regulators

Extra dive regulators?

Repair kits for diver air lines

Extra diver air lines?

Extra air fittings

Extra water pressure and intake hoses

Extra water hose fittings

Extra rubber hose seals (each size)

Extra foot valve(intake for water pumps)

Extra suction hose?

Extra face mask(s)

Extra starter & alternator & fuel pump for dredge motor?

Spare tire (if dredge has removable wheels)