By Dave McCracken

To recover finer gold more efficiently, it is necessary to direct finer-sized materials into more-shallow riffles, that require milder water flows to keep them functioning when filled with concentrated material.

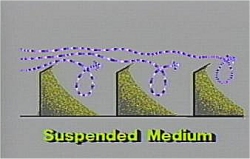

In gold mining, when we talk about gravity-recovery systems (as opposed to chemical-recovery systems), we are basically talking about the creation of a suspended medium. A suspended medium is a condition of fluidity where materials are allowed to separate because of their relative weights.

In gold mining, when we talk about gravity-recovery systems (as opposed to chemical-recovery systems), we are basically talking about the creation of a suspended medium. A suspended medium is a condition of fluidity where materials are allowed to separate because of their relative weights.

Since gold is around six times heavier than the average of other materials which make up a streambed, if you pass raw streambed material through the right kind of suspended medium, you are able to drop the gold to the bottom, and direct the lighter materials off the top as tailings.

As an example of this, if you dropped some gold onto the hard ground, even though the gold is much heavier than the material making up the ground, because the ground is somewhat hard and compacted, it would probably take a very long time for the gold to work its way through to the bottom of the material in that compacted state.

But if you dug up all that ground (and gold), and dumped it into a raging river during a major flood storm, the material would all get churned into a liquid slurry as it is washed downstream in the river, and the gold would very quickly work its way down through to the bottom of the slurry. This is because the slurry is in a liquefied state of suspension, where heavier particles can easily penetrate downward, because gravity is pulling on them much harder than the lighter materials.

There are different ways to create suspended mediums so that gold can be recovered from streambed materials. Mechanical jigs create a pulsating medium within a chamber that keeps water and material in a state of fluid suspension. Oscillating sluices create a left and right movement (similar to panning) as material is washed over top by a mild flow of water. Shaker tables use a finely-tuned vibrating action, with a very mild flow of water, to separate material by weight. Because these systems use mechanics to help keep or create a suspended medium, we refer to them as “mechanical recovery systems.”

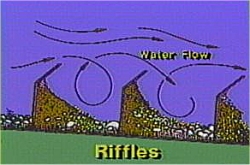

Most recovery systems on suction dredges use fixed riffles to trap gold out of lighter streambed materials as they are washed through a sluice box by a flow of water. Riffles are baffle-like obstructions, fixed in place along the bottom of the sluice box. They are designed and positioned so that there is a back-pressure created that sucks water and material behind the riffles from the flow over top. When the correct water-flow is directed over a riffle, the back pressure keeps the area just behind the riffle in a state of continuous fluid suspension. This creates a medium where the heaviest material (gold) is allowed to concentrate.

Gold recovery systems that use a flow of water over riffles are called “fixed recovery systems.”

Classification (sizing of material) is the key to fine gold recovery. This is true in both fixed and mechanical-type recovery systems. In general terms, this means that the finer (smaller) in size that you want to recover gold efficiently, the more closely the material must be sized, and the more finely-tuned the suspended medium must be to facilitate the separation.

As an example to put this in perspective, the water flow it would take to move a 5-inch (diameter) rock will likely be violent enough to wash away a fine particle of gold. And vise-versa: A suspended medium tuned so gentle as to allow fine particles of gold to efficiently separate from lighter streambed materials would be completely overwhelmed by a 5-inch rock.

The general idea is that if you want to efficiently recover finer-sized gold, you have to first separate it from larger-sized material. This is accomplished by screening. The process of screening is called “classification.” Classified material(s) can then be directed into a recovery system that has slower water and more gentle suspended medium(s).

What do I mean by a “gentler suspended medium?” In this discussion, I am mainly talking about the size of riffles. Because, the bigger (deeper) the riffle, the greater (and more violent) water-flow required to maintain a suspended medium of water and material behind the riffle.

Let’s talk a little about what happens behind the riffle in a sluice box. If you only run water over the box, it does not take very much water-flow to maintain fluid movement behind the riffle, because there is nothing solid to obstruct the flow. But the average streambed material (rocks, gravel and sand) weighs around 4 times more than water. This means water-flow and turbulence must be dramatically increased to keep material in a suspended state behind a riffle. The deeper the riffle, the greater the volume and weight of material which must remain suspended – so the greater the water force (and violence) needed to keep a riffle from packing up.

What is “packing up?” That is when you overwhelm a riffle with too much weight of material (rocks, sand, silt), and the suspended medium is lost. When the suspended medium is lost, most of the riffle will no longer concentrate the heaviest materials as they are washed over the sluice box.

Keep in mind that when a riffle is operating correctly, it will continue to concentrate the heaviest materials that are passed through the suspended medium.

At the beginning of a production-run, the specific gravity of the average material behind a riffle will be similar to the average specific gravity of the raw material found in the streambed. For the purposes if this discussion, let’s say this is around 4 times the weight of water. But as other heavier materials like iron (specific gravity of around 8) flow into the riffles, the heavier materials will displace lighter materials, and the materials behind the riffle (called “concentrates”) will become heavier. Each area is different, but it generally does not take long to accumulate concentrates in a sluice box that are around twice as heavy as the average raw material being processed. Heavier materials are usually associated with iron, and dark-colored by nature. These are often referred to as “black sands.”

The heavier the concentrate behind a riffle, the more water-flow and turbulence is required to maintain a suspended medium. The deeper the riffle, the more it will become overwhelmed by the increased accumulation of heavy material. So a deeper riffle requires a faster, more violent flow to keep it working as the concentrated material behind the riffle becomes heavier.

On the other hand, the shallower the riffle, the less water-force it takes to maintain a suspended medium behind the riffle. Less water force and violence will allow smaller particles of gold to settle.

But a shallow riffle also requires that the water flow be reduced. This is because a shallow riffle will not create enough protection behind it to prevent turbulent flows from boiling fine gold away. What do I mean by “boiling?” I mean that if you put too much water-flow over top of any riffle, the suspended medium becomes so violent that even the heaviest particles can be washed away.

Here is what I am saying: If you want to recover finer gold more efficiently, then it is necessary to direct finer-sized materials into more-shallow riffles, that require milder water flows to keep them functioning when filled with concentrated material.

But the problem with suction dredges is that we are sucking up a lot of rocks! Let’s just use the example of a 5-inch dredge. The nozzle-restriction will allow a 4.5-inch rock to be sucked up into the sluice box. And there must be enough water-flow through the sluice to keep the 4.5-inch rocks, and everything else that is being sucked up, flowing through and out as tailings. Otherwise, the material will build up on the dredge and sink it in very short order!

So initially, we are dealing with a water-force through the sluice box that will wash 4.5-inck rocks all the way through. That is a lot of force. And the force is turbulent.

Part of the reason why a rock is moved by a water-flow is because it is being pushed along by the water. A nearly-equal reason is that it is also being pulled along by the vacuum that is created behind the rock as the water flows around it. The vacuum behind a rock creates enormous turbulence that will affect anything it comes in contact with – including small particles of gold. The turbulence associated with the movement of a 4.5-inch rock is a lot, compared to the mild state of suspension necessary to allow a fine-sized particle of gold to settle behind a short riffle.

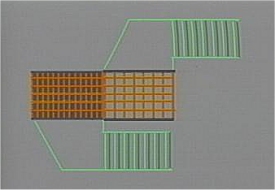

Since we must suck up rocks in dredging, the bigger rock we can suck up, the fewer we have to move out of the way by hand. Therefore, the first priority in the recovery system is to separate the big rocks away from where we want to recover the fine-sized gold. We do this by dropping the smaller-sized materials through a classification screen, and then directing them into slower-moving recovery systems. Sometimes, we are even able to screen two different sized products, and direct each into a separate recovery system, where the suspended mediums can be adjusted accordingly.

But the one mistake I often see is that the pre-sized materials are usually being directed into slower-moving recovery systems that are using deep riffles. As these riffles do not have enough water-flow directed over them to create the required suspended medium, they pack up and don’t work very well. What I mean by this is that most of the space behind a larger riffle can pack up. Sometimes it is only the surface area behind a big riffle that is working, while the rest of the area behind the riffle is packed solid.

But the one mistake I often see is that the pre-sized materials are usually being directed into slower-moving recovery systems that are using deep riffles. As these riffles do not have enough water-flow directed over them to create the required suspended medium, they pack up and don’t work very well. What I mean by this is that most of the space behind a larger riffle can pack up. Sometimes it is only the surface area behind a big riffle that is working, while the rest of the area behind the riffle is packed solid.

Bigger is not better when it comes to riffles in a fine-gold recovery system. In fact, it can be worse.

Here is a substantial explanation of the system which we have developed to effectively recover more fine gold on our conventional suction dredges. It combines two classification screens to more-effectively separate material-feed into three size-fractions, each which is directed into a different recovery system. The smallest gold particles (which are most difficult to recover) are directed into low-profile riffles along the bottom of the sluice box which have long been proven to be very effective at trapping fine gold.

Here are some things to look for to get a better idea if a riffle is working for you:

1) The material behind a riffle should be visibly dancing during normal operation. You should be able to see that all of the material there is in a continuous state of vibration and movement. This can be deceiving, however. Because sometimes, only the surface of the material behind a riffle is in movement. Everything under the surface can often be packed up.

This is almost certainly the case; if after you shut down, you scrape behind the riffle and find that just below the surface of black sand, it is all packed up with lighter, blond-colored material. In this case, you will have to decide if you need to increase the water flow and violence (which will make it harder to settle fine gold) or shorten the riffle.

Shortening the riffle is usually the best solution.

Please don’t get me wrong here. I am not talking about the riffles that get big rocks passed over top of them. I am talking about the riffles where you direct pre-sized, smaller material.

2) Do some controlled tests at production-speed (meaning while someone is sucking material into the dredge’s suction nozzle or feeding material into a sluice), while feeding a pre-weighed amount of fine-gold into the system. You can either catch and test the tailings, or you can process the gold from the recovery system (or both), to evaluate how well your recovery system is working.

Here is where you can buy panning ore which contains fine gold.

If you are losing gold from a fixed recovery system, it will come down to either a screening system that is not working very well (to separate the fine gold from the big rocks that must be washed away using heavy force), or a bad relationship between the flow of water and depth of riffles in the fine-gold recovery system.

The answer is to just keep working at it until you get it right.

Okay; so, if bigger and deeper riffles are not the answer to recovering fine-gold from pre-sized material, how small and shallow should you go? Weight and shape-characteristics of the average streambed material in each area may be a little different. For example, crystalline, angular-type material requires more force and turbulence to keep it moving along. So there is not a fixed answer that will work perfectly in every single situation.

However, as a general guideline, I would say that the depth of a riffle should not be much more than the maximum size of material that is being directed there. In other words, if a 3/8-inch screen is being used to pre-size material, you probably don’t want to use riffles much deeper than 3/8-inches. Then you set the water-flow to keep those riffles fluid when there is an accumulation of concentrated material behind them. This is not a fixed formula. You will have to use your own best judgment to dial it in right based upon your local conditions.

Remember: If you use shorter riffles, you must slow down the flow over top of them to keep from boiling-out your fine gold. Slower water, and less violence, allows for finer particles of gold to settle – as long as a suspended medium is maintained behind the riffle. If you can keep the black sand in movement, without boiling out the riffles, you will have a great recovery system. Because gold is around 2.5-times heavier than iron, fine particles of gold will displace the iron behind the riffles, as long as there is movement there.

- Here is where you can buy a sample of natural gold.

- Here is where you can buy Gold Prospecting Equipment & Supplies.

- More About Gold Prospecting

- More Gold Mining Adventures

- Schedule of Events

- Best-selling Books & DVD’s on this Subject