THIRD QUARTER, JULY 2015 VOLUME 29, NUMBER 7

Newsletter By Dave McCracken General Manager

This is turning out to be a very low water year along the Klamath River; the lowest I have seen in a very long time; and we still have several months in front of us before the season is over. The water has dropped by at least a foot since we did our first weekend group outing of the season several weeks ago. You guys might recall from last month’s newsletter that we have discovered a massive surface gold deposit on our K-23AA property which is located around 7 miles downstream of Happy Camp. Since the discovery is a pretty long walk from the nearest easy place to gain access to a boat, a walk that many people might want to make in hundred-degree weather, our biggest challenge this season has been in coming up with creative ways to move large numbers of people to and from the rich gold deposit by boat.

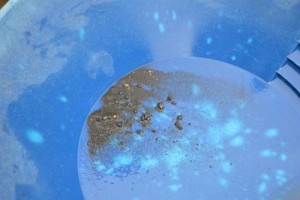

Typical pan sample out of the new deposit!

We worked out a pretty effective method several weeks ago by towing one of our larger Colorado River rafts behind my jet boat. We were able to transfer around 20 people at a time. That worked out well. Surprisingly, it was not the movement of people that was difficult. The hard part was towing the empty raft back up through two sets of pretty gnarly rapids so that we could pick up another load of people. All in all, with 120 people, this meant towing the raft up through two sets of rapids 24 times during the first project. My jet boat was getting so tired, there were a few trips towards the end where I had my doubts we would make it!

As it was, the first project of the season went really well. This new deposit appears to be the richest and largest surface gold deposit (out of the water) we have ever located. We recovered 18 pennyweights (9/10ths of an ounce) of beautiful gold in several hours of digging on the first project of the season, which is at least a 5-year record.

The first thing I did after the first project was finished was tow my tired jet boat over to the shop for a full tune-up. Because it is the mechanic’s busiest time of the year, I did not get the boat returned to me until the Friday morning before the start of the second project (last weekend). By then, John Rose was telling me that the river had already dropped too low, and the rapids were too steep, for us to use boats to move people. Oh my!

This is only the second time in 30 years that we have found rich, virgin stream bed out of the water!

This gold deposit is too rich to abandon!

This gold deposit is too rich to abandon!

Very fortunately for the Club, we have a new member this year, Dan Baker, who brought along the strongest and nicest jet boat I have ever seen for maneuvering the Klamath River in low water. Dan also brings along other valuable attributes, like being able to capture images and video, and do an excellent job of editing. You will see a bunch of his good work being put up on our new Facebook page. All or most of the images and video in this newsletter were produced by Dan and our new office manager, Tony.

In any event, while most of our other project helpers were of the opinion that we were going to need to walk people in for the weekend project, Dan was telling me that his jet boat was easily making it up and down through the section of Klamath River where the project was going to take place. The weatherman said it was going to be 100+ degrees on Saturday afternoon. So Dan and I, with some of our helpers, were out on the river Friday afternoon, using two jet boats and our large rubber raft working out how we could move people around on the river.

The interesting thing about the Klamath is that when the water drops, the rapids get steeper, shallower and faster, and the waves get taller. So while the slower sections of river get easier to traverse, the faster sections get more difficult as the water drops. Fortunately, and to my great relief, we discovered on the first trial run that we were going to be able to use my jet boat, once again towing the large raft, to move people to and from the worksite, just like we did during the earlier project. The ride through the rapids was going to be faster with more splashes; but members were going to be alright with that in the hot weather.

The interesting thing about the Klamath is that when the water drops, the rapids get steeper, shallower and faster, and the waves get taller. So while the slower sections of river get easier to traverse, the faster sections get more difficult as the water drops. Fortunately, and to my great relief, we discovered on the first trial run that we were going to be able to use my jet boat, once again towing the large raft, to move people to and from the worksite, just like we did during the earlier project. The ride through the rapids was going to be faster with more splashes; but members were going to be alright with that in the hot weather.

The big challenge was how we were going to move the raft back up through the rapids. Since his jet boat is stronger than mine, Dan offered to tow the raft upriver.

So there we were on the first try with several of us in Dan’s boat and Derek Eimer riding along in the rear of the raft. Dan’s boat had plenty of power to do the job; and it initially looked as though the raft would go along with no problems. But about half way through, a very large stationary wave in the rapids came over the front of the raft and caused the front end to dive just like a submarine. It all happened in a split second. Derek was lucky he was not washed right out of the rubber raft!

I have more experience driving boats on the Klamath River, so Dan insisted that I give it the second try while he filmed the adventure. Once again, it was going just fine until one of the large stationary waves in the rapids caught the front of the raft and drove it underwater, nearly filling the boat with water. Here is some video that Dan captured during our second try:

These kinds of problems are best worked out in advance of having 100+ members out along a remote section of the river where the only way back to the cars is either by boat or swimming!

For our third attempt, Rich Krimm came up with the idea of rigging a tow harness from further to the rear of the raft and running it underneath to the front so that the pulling would help lift the front of the raft higher above the water. We had some extra rope in my jet boat and made quick work out of rigging the harness. And while the front of the raft appeared to be further above the water, that stationary wave in the rapids overwhelmed the raft just like during our earlier attempts. By now, Derek was looking half drowned. But he was still laughing and enjoying the adventure.

One of the many reasons I love managing The New 49’ers is that I am able to get out with other very capable guys (and gals) and confront some of Mother Nature’s most difficult challenges, and usually, but not always, find a way to overcome them. We were all having a blast out there!

Even though we were having fun, not a single one of us ever let our guards down to the dangers involved. The Klamath River is so powerful; it can snuff the life out of a person in just moments. When things go wrong in a boat on the river, they go critically wrong; and rather than worrying about saving the boat, the emergency can immediately turn into trying to live through the experience. The more extreme the conditions, the less margin there is for error; and the worse things are going to turn out if we make a mistake. Believe me; I have experienced a whole lifetime of making mistakes!

After submarining the raft three times, we came up with a whole new idea of tying a harness further forward on Dan’s jet boat, pulling the front of the raft right up onto the backside of the jet boat and securing it so it would piggyback up through the set of rapids. This plan worked out great, except that the powerful blast out of Dan’s jet boat made for an interesting and challenging ride for Derek. Several times, it looked like the raft would completely flip over! Ultimately, we worked out a system where Derek and Dyton Gilliland would shift their weight one way or the other to compensate for which side of the jet blast the raft was riding on. Here is some great video showing how we finally worked out a technique to move the raft upstream.

We did several trial runs up through the rapids just to make sure we could rely on the technique once we had a bunch of New 49’ers to move around on the river. The technique worked great, and we were all set for another weekend project on the river. Cool!

We did several trial runs up through the rapids just to make sure we could rely on the technique once we had a bunch of New 49’ers to move around on the river. The technique worked great, and we were all set for another weekend project on the river. Cool!

By Saturday morning, we had 130+ people signed up for the weekend project. This was an all-time high for the second project of a season. Always in the past, we have a large group on the first project, once as many as 137 people. Then the numbers drop off dramatically as we progress through the season. But not this year!

This turned out to be an enthusiastic bunch of New 49’er members who were out to have fun and get some gold! After going over some theory on Saturday morning, and a break for lunch, our large group arrived down on K-23AA at around 1 pm. This is when the heat of the day really sets in. Someone measured the temperature at 109 in the shade, and 123 out on the rocks in the direct sun. That’s hot!

Fortunately, since we have already located the pay-dirt in this massive gold deposit, Saturday’s objective for this season’s projects is mainly to teach beginners how to operate a gold pan. We take this part very seriously, because panning is the beginning of the prospecting learning curve. You cannot sample for high-grade gold deposits unless you can effectively work a gold pan.

All of our project helpers were waiting for us when we started arriving by boat with 20 people at a time. Using our new method of moving the raft upriver, it only took us around 30 minutes to get everyone to the worksite. It went just like clockwork.

By the time Dan and I tied off our jet boats, nearly everyone was already panning up a storm. Participants get to keep all the gold they can find on Saturday afternoon. So this bunch was really going at it! Here is some video that captured a lot of the action.

Boy was it hot out there on this Saturday afternoon! Once people started collecting under the shades we have set up out there, I took it as a sign that it was time to start ferrying people downstream to where they had parked their cars earlier in the day. With some excellent teamwork, it took 5 boatloads to get everybody back across the river through another set of rapids about a half-mile downriver.

Saturday potluck was a full house; I’m guessing about 180 people. There was lots of food, and I could barely hear myself think over the enthusiastic chatter of the very large group. This type of noise is always music to my ears!

Because Sunday is the day we work hard, we always get out there early. This is so we can get the work finished and be off the gravel bar before the heat of the day sets in. When I arrived at 6:15 am, there was already a long line of participants putting on life jackets to board the boats. Once again, it only took our experienced crew around 30 minutes to get everyone on the worksite.

The mission on Sunday is to process as much of the pay-dirt as possible through our high-banker recovery systems without killing off the participants. Fortunately, the sky was overcast and rewarding us with a very mild drizzle. In just a short time, our experienced team members had the whole crew organized into groups performing different functions. Some were moving rocks out of the way. Others were using garden picks to drag pay-dirt into piles. Then others were transferring the pay-dirt into plastic buckets. More people were packing the buckets to the recovery systems, where still others were feeding the material. There was a whole lot of productive activity going on! Dan captured some of the action, along with my explanation, in the following videos:

Once things were well underway, Dyton and I took the time to show most of the participants how to reach out and carve out “top cuts” to increase the amount of volume a person can process. This is also something we do to obtain maximum production in gold dredging. The more pay-dirt you process, the more gold you end up with at the end of the day. It is as simple as that. Dan captured some of the demonstration on video:

Several participants were vacking gold out of the bedrock traps as we uncovered them.

Craig Colt, who has been helping on these projects for many years, devoted most of Sunday panning samples of the material people were digging. The purpose of this is to identify the richer-paying areas and direct the digging program into more productive pay-dirt.

As we have worked forward in this deposit, we have discovered that there is an ancient, orange-colored streambed material that is paying the best. The good thing is that the material in most of this deposit is usually 2 feet or less to reach bedrock. Bedrock is where we expect to find gold nuggets!

This is one pan sample off the bedrock at Ground Zero!

While most of the group was working a long stretch of bedrock we uncovered at the base of the deposit, several others climbed up the hill to where the original gold discovery was made. We fondly refer to this spot as “ground zero.” The material is a bit deeper over there. We attempted to reach bedrock at ground zero during the first project, but didn’t quite make it. Several very determined guys reached bedrock this time in about 5 feet of virgin streambed which was producing gold all the way through. Then Dyton took a careful sample off the bedrock and produced a very favorable result. Now we had confirmation that this rich gold deposit is so large, we will be working it for many years to come. Here was my explanation:

We were getting nuggets out there, too!

We were operating three high-bankers on Sunday, feeding material as fast as the machines could process the gold. Once we put a few hours of good production through the high-bankers, we normally take a moment to clean out only the high-grade portion of a single high-banker. We screen the material to pick out any nuggets. Then we pan the rest down so we can get an idea how well we are doing. Everybody agreed we were doing really well! Dan captured the excitement on video:

Showing off the gold always motivates participants in these projects to redouble their efforts, and this time was no exception! So I was met with some disappointment about an hour later when I went around and told everyone to finish up the final buckets and start reclaiming our excavation back to the normal contour of the bank. Some just kept on digging, anyway. There were at least 15 full buckets of rich pay-dirt delivered to the high-bankers even after we had shut them down to do final clean-up! In hindsight, if we had processed those, we likely would have met my target of recovering a full ounce of gold.

It was about 11 am when we started winding things up. This means storing the gear away and performing an initial clean-up to reduce the amount of concentrated heavy material accumulated from the 3 high-bankers. We usually do this part with a Le Trap Gold Sluice. This is one of the big rewards of the day, because the process reveals to everyone how their hard work has been converted into raw gold. Every scoop from the buckets of concentrates produced a trail of gold into the Le Trap. We were going to have a good clean-up! Dan caught the excitement on video:

Ferrying everyone down through another set of rapids to the boat landing where their cars were parked just added more fun and excitement to an already excellent day.

Dave and Craig Colt demonstrating the final clean-up steps.

We all met up at the Grange Hall a few hours later to complete the final clean-up process and split the gold. In all, we recovered 18.6 pennyweights, which included 27 nice gold nuggets. Everyone who participated received an equal share of the gold by weight. There were a lot of happy faces as we handed the shares out. For many, it was the first gold they had ever mined.

Truthfully, before we weighed the gold, it looked to me like it was at least a full ounce. That’s what I was hoping for. But we didn’t quite make it. We will just have to take another shot at it on the next project!

By the way, you guys don’t have to wait for the monthly newsletter to see the adventures we are enjoying on the Klamath River. Our new video team is posting great material on the New 49’er Facebook page nearly every day. Just as one example here is the whole project adventure video which our guys put up on Facebook just a day or so afterwards.

Join us for our remaining Weekend Group Mining Projects this Season!

There is a learning curve to successful gold prospecting. One of the most effective methods of progressing through the learning curve is to go on prospecting adventures with others who are more experienced than you.

Our 2-day Group Mining Projects are one of the primary benefits of New 49’er membership which set us apart from other mining associations. All weekend events are free to Full & Associate Members.

Remaining Schedule of 2015 Events: July 18 & 19; August 8 & 9; and August 29 & 30.

Schedule of Events

Legal Fund Winners!

We completed our most recent New 49’ers Legal Fund Drawing for 20 tenth-ounce American Gold Eagles and 2 fantastic Garrett gold detectors at our Saturday evening potluck on the evening of 27 June. There were a lot of members present, though not a single one of them won a prize. Not that anyone was disappointed. These legal fund raisers are more about pulling together to defend something that is much more important than prizes. Here follows some video which captured the event:

Here are the winners:

Grand Prize: Garrett ATX Metal Detector: Gerald Fawcett of Anchorage, AK

Second Prize: Garrett AT Gold Detector: Chris Edmondson of Mission Viejo, CA

American Gold Eagles: Howard Charleboix of Great Falls, MT; Robert Lake of Brookings, OR; Michael Ward of West Point, UT; Edward Murphy of Somes Bar, CA; Larry Buzzell of Sequim, WA; Michael McLeod of Carson City, NV; Greg A Miller of Coarse Gold, CA; Eugene Lewis of Gig Harbor, WA; Daniel Cutshell of Bishop, CA; David Ames of Silverton, OR; Joseph Burda of Pacifica, CA; Dennis Taylor of Sherwood, OR; Daniel Court of La Pine, OR; Michael Dickman of Manteca, CA; Jerry Keith of Wake Forest, NC; Greg Miller of Coarse Gold, CA; Bill Kerr of Klamath Falls, OR; Randy Watkins of Sparks, NV; Gerald Hawley of Kalispell, MT; Floyd Parker of Kannapolis, NC

Montine in our office (530 493-2062) is making contact with all the winners.

I want to thank Garrett Metal Detectors for their generous support of our efforts to preserve the industry. When you are considering what kind of equipment to buy for your prospecting activities, I sincerely request that you take a strong look at the products being offered by the industry manufacturers who are supporting all of our combined efforts.

I also need to personally thank all of you who participated in this fund-raiser. We could not play our part to help defend the small-scale mining industry if it were not for your ongoing support.

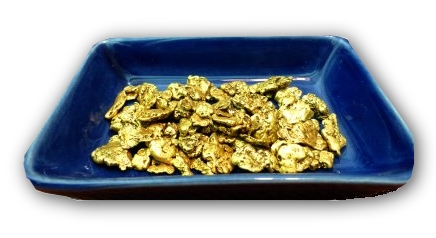

Any legal contributions which have arrived in our office after this drawing will automatically generate tickets for the next New 49’ers Legal Fund drawing. The new drawing will be for two ounces of beautiful gold nuggets (image above). Those will be split into a 1-once grand prize and four quarter-ounce prizes. There will also be 10 tenth-ounce American Gold Eagles and 10 American Silver Eagles. That’s 25 prizes worth winning!

Any legal contributions which have arrived in our office after this drawing will automatically generate tickets for the next New 49’ers Legal Fund drawing. The new drawing will be for two ounces of beautiful gold nuggets (image above). Those will be split into a 1-once grand prize and four quarter-ounce prizes. There will also be 10 tenth-ounce American Gold Eagles and 10 American Silver Eagles. That’s 25 prizes worth winning!

The drawing will take place at the close of business at our headquarters in Happy Camp on Friday, 30 October. You do not need to be a member of our organization to participate. You are welcome to be at the drawing, but you do not need to be present to win.

Our office will automatically generate a ticket in your name for every $10 legal contribution we receive ($100 will generate 10 tickets). There is no limit to the size or frequency of your contributions, or to the number of prizes you can win. Look for our new Paypal contribution link here. Your legal contributions can also be arranged by calling (530) 493-2012 or by mailing to The New 49’ers Legal Fund, P.O. Box 47, Happy Camp, CA 96039.

Remember, all contributions to The New 49’ers Legal Fund are tax deductible.

Once again; thank you guys very much for standing behind us!

We are Not Going to Have a Hassle-Free 2015 Dredging Season

Here is the bad news: I’m disappointed to announce that our motion in San Bernardino Superior Court for a Temporary Restraining Order (TRO) to allow suction dredging on our extensive New 49’er properties in conformance with the 2012 regulations was denied by the judge on the 9th of July.

I believe this was likely our final opportunity to obtain hassle-free suction dredging in California during the 2015 season. By “hassle-free,” I mean that we continue to believe California’s moratorium is not legal; and that suction dredgers are not likely to be prosecuted, even if they are written a criminal citation. But suction dredgers do have the risk of their equipment being confiscated until some later time. So you dredge at your own risk for the time being.

We will now switch gears into appealing San Bernardino’s recent Rulings to deny any meaningful relief to suction dredgers even after the court has Ruled and Ordered that the moratorium is unconstitutional — which State authorities continue to enforce. There is also the landmark Rinehart Decision which is being reviewed by the California Supreme Court. It is not an unreasonable expectation that we can have these matters resolved in time for our 2016 season.

All I can say is that we have done our very best to bring about a hassle-free 2015 dredging season. I thank everyone who has supported our efforts. All we can do is keep trying.

Meanwhile, just in case you do not know, this ongoing conflict with the State only affects motorized suction mining within 100 yards of California’s active waterways. It does not have anything to do with the other types of prospecting or mining that we do in California. Unaffected prospecting activities include panning, sniping & vack-mining, sluicing & high-banking, electronic prospecting and other types of prospecting that do not use a suction nozzle within 100 yards of an active stream, river or creek. It also does not affect our Group Weekend Projects.

To continue prospecting the bottom of active waterways, some members have converted to underwater crevicing, using the hookah and pump from their 5 and 6 HP motors on floating platforms to provide air for breathing and a jet of water to help move material out of the way, thus coining the new method as “underwater blow mining.”

There are no seasons imposed upon these other types of mining activity. In other words, you can do them at any time of the year.

Now here is the good news: Just as I am finishing this newsletter, some of our most experienced underwater miners are finishing up a prototype for an entirely new concept in underwater mining with the use of a pressure washer primarily uses a powerful blast of very low-volume water to uncover and free rocks that must be moved out of the way in a submerged streambed. We believe the process may be nearly as effective as suction mining, but without the discharges which anti-mining activists complain so much about. We will be testing and developing the new idea over the coming weeks. Please watch for updates and news on our Facebook page and in next month’s newsletter.

Fire Restrictions

Because of exceptionally dry conditions, the U.S. Forest Service has imposed fire restrictions in the Klamath National Forest as of last week. This means internal combustion engines (like water pumps) cannot be operated on our mining properties unless you are floating them out on the waterway. Since the fire restrictions are likely to continue for the remaining part of this season, you might give some thought to how you can rig up something to float your motor(s). In case you are interested, there are special floats made specifically for this purpose. Please contact Montine for more details: 530 493-2062. You can find out more about what is and is not allowed under these restrictions right here:

Sign up for the Free Internet Version of this Newsletter

We strongly encourage you to sign up for the free on line version of this newsletter. The Internet version is better. This is because you can immediately click directly to many of the subjects which we discuss; because the on line version is in full color; because we link you directly to locations through GPS and Google Earth technology; and because you can watch the free video segments which we incorporate into our stories. Actually, the video segments show the adventures better than I can write them!

Signing up also places you on our Political Action Team. Things happen so fast these days; it takes too long to organize political action through the U.S. mail. As an example, by contacting our supporters this way, in a matter of hours, we recently generated a large bundle of letters to the California Supreme Court. All of these future battles will be organized over the Internet since it is so much faster. Please join us in the battle to maintain our remaining freedoms!

Sign up for our Free Internet Newsletter!

Note: You are free to unsubscribe anytime just by clicking a link if you decide to do so.

The New 49’ers Prospecting Association, 27 Davis Road, Happy Camp, California 96039 (530) 493-2012 www.goldgold.com

Print This Post

Print This Post

Mother Nature sure has given us a variety of weather so far this winter mining season in Happy Camp. There has been plenty of rain, some freezing weather in the mid-twenties, snow, and sometimes temperatures up in the mid-fifties. But even the worst weather hasn’t stopped some ambitious miners from seeking their fortunes; they just modify their prospecting methods accordingly.

Mother Nature sure has given us a variety of weather so far this winter mining season in Happy Camp. There has been plenty of rain, some freezing weather in the mid-twenties, snow, and sometimes temperatures up in the mid-fifties. But even the worst weather hasn’t stopped some ambitious miners from seeking their fortunes; they just modify their prospecting methods accordingly. I was telling some other members about it over coffee at the office one morning. That’s when Jon Martin spoke up and said he was mining in the creek close to his camp using a sucker gun and sluice box. I asked if I could video the system he was using. “Sure” he said.

I was telling some other members about it over coffee at the office one morning. That’s when Jon Martin spoke up and said he was mining in the creek close to his camp using a sucker gun and sluice box. I asked if I could video the system he was using. “Sure” he said. My wife Cheri and I joined the New 49’ers in 1998. We just hand mined, sluiced, gold panned and metal detected for gold nuggets during the first few years. Talking about great adventure! We always brought our kids, grand kids, and as many other kids that wanted to come. We would go rafting, or over to the Oregon caves, or just have picnics on the beach and swim. I would always do some gold prospecting, sometimes crevassing with mask and snorkel — or just prospecting on the creeks. We always found some gold. My granddaughter Lily prospected alongside me for a month last summer. Those are more memories that neither of us will ever forget. I’m looking forward to her being here during the 2016 season, also. You spend some quiet time on the river with your grandkids, and the memories are more valuable than the gold you are hunting for!

My wife Cheri and I joined the New 49’ers in 1998. We just hand mined, sluiced, gold panned and metal detected for gold nuggets during the first few years. Talking about great adventure! We always brought our kids, grand kids, and as many other kids that wanted to come. We would go rafting, or over to the Oregon caves, or just have picnics on the beach and swim. I would always do some gold prospecting, sometimes crevassing with mask and snorkel — or just prospecting on the creeks. We always found some gold. My granddaughter Lily prospected alongside me for a month last summer. Those are more memories that neither of us will ever forget. I’m looking forward to her being here during the 2016 season, also. You spend some quiet time on the river with your grandkids, and the memories are more valuable than the gold you are hunting for!

Well, the hot summer days and warm summer nights with fifteen hours of daylight have ended for this year. Most of the miners who summer in

Well, the hot summer days and warm summer nights with fifteen hours of daylight have ended for this year. Most of the miners who summer in  Well, after I got things squared away with Loki, he realized we were there to work, not play. And I have to admit that he did try to help me with the shoveling. I’m sure he thought he was helping.

Well, after I got things squared away with Loki, he realized we were there to work, not play. And I have to admit that he did try to help me with the shoveling. I’m sure he thought he was helping.

Some of these guys are coming back with stories which border on unbelievable, or at least unexplainable, encounters with Bigfoot. The encounters are happening too often, and in too many places, to just discount as wild imagination. For example, Gabe Garrison was recently on an extended hiking/camping trip with two New 49’er members into the headwaters of Indian Creek in search of an old historical gold mine. They were way out in the wildlands just a mile or two from the Oregon Border. Shortly after setting up camp one evening, something started a landslide from the high peaks just across the canyon. They didn’t think much about it until a little while later when they heard a distinct signal just out of sight a short distance away. The signal was unmistakingly from two sizable pieces of wood being banged together; a noise that was clearly not from natural causes. Just a little while later, a similar banging signal came from just out of sight on the other side of their camp.

Some of these guys are coming back with stories which border on unbelievable, or at least unexplainable, encounters with Bigfoot. The encounters are happening too often, and in too many places, to just discount as wild imagination. For example, Gabe Garrison was recently on an extended hiking/camping trip with two New 49’er members into the headwaters of Indian Creek in search of an old historical gold mine. They were way out in the wildlands just a mile or two from the Oregon Border. Shortly after setting up camp one evening, something started a landslide from the high peaks just across the canyon. They didn’t think much about it until a little while later when they heard a distinct signal just out of sight a short distance away. The signal was unmistakingly from two sizable pieces of wood being banged together; a noise that was clearly not from natural causes. Just a little while later, a similar banging signal came from just out of sight on the other side of their camp.

Perhaps Dickie’s most compelling encounter is when he was prospecting up on our Indian Creek Claim near

Perhaps Dickie’s most compelling encounter is when he was prospecting up on our Indian Creek Claim near

The

The

Our second attempt involved tying the raft as close to my jet boat as possible and allow the raft to ride on the jet blast from, my motor. This worked best once we removed all passengers from the raft. Once we had that worked out, we made two flawless passes both up and down the river and came to the fortunate conclusion that we were going to be able to do the weekend project once again in our already-established

Our second attempt involved tying the raft as close to my jet boat as possible and allow the raft to ride on the jet blast from, my motor. This worked best once we removed all passengers from the raft. Once we had that worked out, we made two flawless passes both up and down the river and came to the fortunate conclusion that we were going to be able to do the weekend project once again in our already-established  Participants get to keep all the gold they find on Saturday; so there was no holding back this

Participants get to keep all the gold they find on Saturday; so there was no holding back this

Sometime around 11 am, we shut everything down, put the gear away, leveled off our tailings piles to reclaim the visible disturbances we made; and then we did a

Sometime around 11 am, we shut everything down, put the gear away, leveled off our tailings piles to reclaim the visible disturbances we made; and then we did a

This gold deposit is too rich to abandon!

This gold deposit is too rich to abandon! The interesting thing about the Klamath is that when the water drops, the rapids get steeper, shallower and faster, and the waves get taller. So while the slower sections of river get easier to traverse, the faster sections get more difficult as the water drops. Fortunately, and to my great relief, we discovered on the first trial run that we were going to be able to use my jet boat, once again towing the large raft, to move people to and from the worksite, just like we did during the earlier project. The ride through the rapids was going to be faster with more splashes; but members were going to be alright with that in the hot weather.

The interesting thing about the Klamath is that when the water drops, the rapids get steeper, shallower and faster, and the waves get taller. So while the slower sections of river get easier to traverse, the faster sections get more difficult as the water drops. Fortunately, and to my great relief, we discovered on the first trial run that we were going to be able to use my jet boat, once again towing the large raft, to move people to and from the worksite, just like we did during the earlier project. The ride through the rapids was going to be faster with more splashes; but members were going to be alright with that in the hot weather.

We did several trial runs up through the rapids just to make sure we could rely on the technique once we had a bunch of New 49’ers to move around on the river. The technique worked great, and we were all set for another weekend project on the river. Cool!

We did several trial runs up through the rapids just to make sure we could rely on the technique once we had a bunch of New 49’ers to move around on the river. The technique worked great, and we were all set for another weekend project on the river. Cool!

Any legal contributions which have arrived in our office after this drawing will automatically generate tickets for the next New 49’ers Legal Fund drawing. The new drawing will be for two ounces of beautiful gold nuggets (image above). Those will be split into a 1-once grand prize and four quarter-ounce prizes. There will also be 10 tenth-ounce American Gold Eagles and 10 American Silver Eagles. That’s 25 prizes worth winning!

Any legal contributions which have arrived in our office after this drawing will automatically generate tickets for the next New 49’ers Legal Fund drawing. The new drawing will be for two ounces of beautiful gold nuggets (image above). Those will be split into a 1-once grand prize and four quarter-ounce prizes. There will also be 10 tenth-ounce American Gold Eagles and 10 American Silver Eagles. That’s 25 prizes worth winning!

As they took the time to show us what they had found, they also told us of their personal story; a story which could prompt you to ponder the larger mysteries of fate and hope that affect each of our personal destinies. It turned out that they actually did not intend to sample in this new location at all. Their vehicle had broken down alongside the highway. It was going to take a week for the parts to arrive. Since they were not going anywhere, Dave lowered his raft and prospecting gear down the embankment and decided to make the best use of his time prospecting on the far side of the river. He was rewarded with

As they took the time to show us what they had found, they also told us of their personal story; a story which could prompt you to ponder the larger mysteries of fate and hope that affect each of our personal destinies. It turned out that they actually did not intend to sample in this new location at all. Their vehicle had broken down alongside the highway. It was going to take a week for the parts to arrive. Since they were not going anywhere, Dave lowered his raft and prospecting gear down the embankment and decided to make the best use of his time prospecting on the far side of the river. He was rewarded with

The problem is that this new discovery is in a rather difficult location to gain access with large numbers of people. There is plenty of parking and a rather easy trail from Highway 96 located about a quarter-mile upriver from the deposit. There is a set of rapids between the trail and this new discovery. So while we could transfer people down to the deposit with our large rubber raft, we were not going to be able to get the raft back up through the rapids using its own small outboard motor, even without passengers. There is a trail on the far side of the river. But it’s a long way to walk at the end of a hard day of mining. Anyone who has participated in these projects will tell you that we work pretty hard on Sunday morning, especially when we see how the gold is adding up! So walking out of there is not a great option.

The problem is that this new discovery is in a rather difficult location to gain access with large numbers of people. There is plenty of parking and a rather easy trail from Highway 96 located about a quarter-mile upriver from the deposit. There is a set of rapids between the trail and this new discovery. So while we could transfer people down to the deposit with our large rubber raft, we were not going to be able to get the raft back up through the rapids using its own small outboard motor, even without passengers. There is a trail on the far side of the river. But it’s a long way to walk at the end of a hard day of mining. Anyone who has participated in these projects will tell you that we work pretty hard on Sunday morning, especially when we see how the gold is adding up! So walking out of there is not a great option.

Afterwards, we realized that with a little creative carpooling at the beginning of the day, we can park most of the vehicles down at the Wingate River Access and ferry people downstream from the work site at the end of our day. That will make the process go faster.

Afterwards, we realized that with a little creative carpooling at the beginning of the day, we can park most of the vehicles down at the Wingate River Access and ferry people downstream from the work site at the end of our day. That will make the process go faster.

John: Our office manager, Tony Balderrama, is a dedicated amateur radio operator. He uses the New 49’er radio system to regularly monitor all of the Siskiyou County emergency frequencies. This is because we have so many active members, if there is ever an emergency; we are more likely to find out about it faster over the emergency channels. Later, when I returned to the office, Tony told me he that he took notes of the entire exchange between the warden and his dispatcher. The conversation began at 2:10 pm. “The subject is requesting to be arrested,” said the warden. At 2:20, the dispatcher answered “The Watch Commander says that’s a negative on making an arrest or issuing a citation.”

John: Our office manager, Tony Balderrama, is a dedicated amateur radio operator. He uses the New 49’er radio system to regularly monitor all of the Siskiyou County emergency frequencies. This is because we have so many active members, if there is ever an emergency; we are more likely to find out about it faster over the emergency channels. Later, when I returned to the office, Tony told me he that he took notes of the entire exchange between the warden and his dispatcher. The conversation began at 2:10 pm. “The subject is requesting to be arrested,” said the warden. At 2:20, the dispatcher answered “The Watch Commander says that’s a negative on making an arrest or issuing a citation.”  Derek’s nozzle and hose were gone. True to his convictions, Derek returned with another hose and nozzle and is now back out on the river continuing his

Derek’s nozzle and hose were gone. True to his convictions, Derek returned with another hose and nozzle and is now back out on the river continuing his