By Dave McCracken

Part Three – Sampling is a never-ending process

You would think that sampling could end once you’ve found a pay-streak. Because, once you’ve found a pay-streak, you start your production operation to recover the gold. However, sampling continues on, possibly even to a greater degree, even after you’ve located a rich deposit.

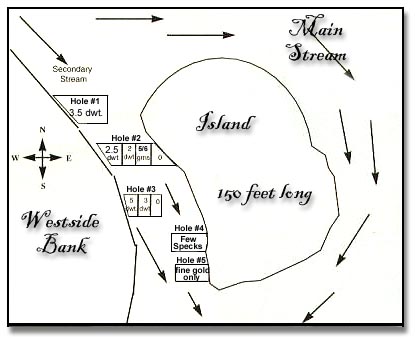

When you locate a deposit that you have determined is good enough to work, your next step is to define your deposit’s boundaries. This takes more sampling. It is generally done by dredging or digging more sample holes. The first and most important boundary you should find, especially if you are dredging, is the lower-end, meaning the downstream-end of the pay-streak. This is because you need to find a place to drop your tailings where they will not end up on top of your gold deposit.

In mining activities of any kind, tailings placement is of primary concern right from the beginning of the operation. You generally do not worry about it too much during sampling, because you have not determined there is a deposit in the immediate location as yet. But as soon as you are certain there is a deposit worth developing, where you place your tailings becomes very important!

In dredging, providing you are going to have the time to develop the entire deposit, you usually back your dredge further down river, dredging sample holes as you go, to locate where the deposit plays out. It is then smart to dredge a few more sample holes below this point to make sure the deposit really did play out where you will put your tailings. Then, start dredging from the tail-end of the deposit, dropping your tailings over the area that you have already worked.

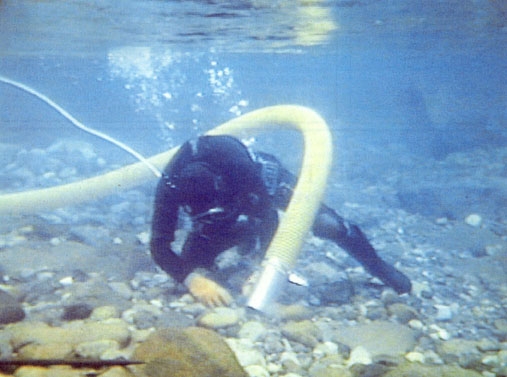

As you work the deposit forward, you also must locate the left and right boundaries of the deposit. This also requires your sampling attention, only in a different way. Rather than dredge or dig sample holes, pay close attention to how much gold you are recovering while continuing to move your production hole in the direction of each side of the deposit. In dredging, if you are into a healthy deposit, you will see gold when you uncover the strata of streambed material where it is located.

As I mentioned in the earlier parts of this series, when you find gold in a sample hole, the first thing to do is establish where it is coming from. Is it from the contact zones between streambed layers or is it coming off the bedrock? This also applies to production mining. You need to know where the gold is coming from so you can watch that particular strata of streambed material closely to make sure it is still paying as you move your production hole forward and toward the left and right side boundaries of the deposit.

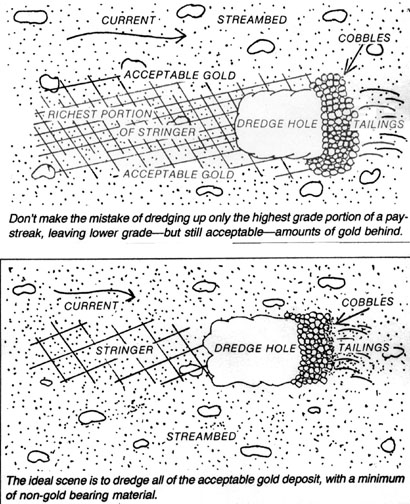

In dredging, if it is a good pay-streak, when the paying strata is uncovered, you can actually see the gold if you slow down and look. You will also see the gold disappear once you extend beyond the boundaries of your pay-streak. It is standard practice to slow down and watch your pay strata closely when production dredging. By following this procedure, you will continue to dredge up pay-dirt with a minimum of non-paying material. This means that the job of sampling never really ends, even when you are mining a good pay-streak; especially when mining a good pay-streak!

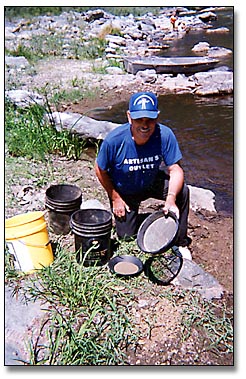

When digging, as in high-banking, you cannot depend as much on seeing your gold as you dig in the pay strata, so it can be necessary to clean-up your recovery system more frequently to make sure you are still mining in a section of the gold deposit. You can also sample the pay strata with a gold pan on a regular basis to make sure it is still paying in sufficient quantities.

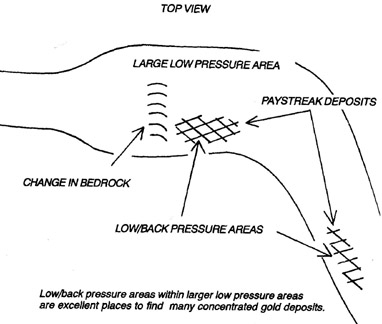

The idea behind a production operation is to mine all of the deposit, while mining as little of the non-paying material outside the deposit as possible. However, you cannot always directly see where the deposit plays out. So you must be constantly watching how well the deposit is paying and where it seems to play out. This can sometimes be difficult to do; because some pay-streaks are not entirely consistent. For example, a non-visible obstruction or change in the bedrock upstream can cause an entire section of pay-streak deposit to boil out and give you the false impression of a boundary–when there might be an even richer section of the pay-streak several feet beyond where it apparently plays out! This has happened to me a number of times when I discovered further upstream that the pay-streak was wider than I thought. Then I had to drop back and pick up what I had missed on my first pass.

Keeping these thoughts in mind, just do your best to figure out what the deposit is doing as you follow it. Every once in a while, it is important to devote some time and energy continuing to sample beyond the apparent boundaries of the pay-streak to make sure you are not missing anything important.

Short of actually finding a rich pay-streak, finding an increase in the amount of gold in a sample hole is the best sign to look for while testing. Finding an increase in gold means more sampling is a good idea in the immediate area.

In the same way, finding a rich pay-streak means much more sampling is justified in that immediate area–especially beyond the apparent boundaries of the pay-streak you are working. This sampling is best done as you move forward, before you start dumping your tailings in that location.

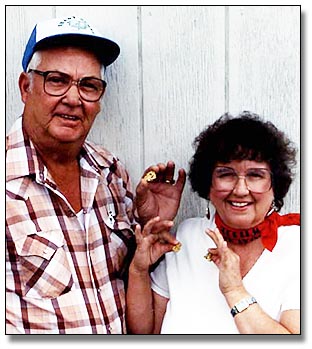

Another important thing is to determine for yourself how much gold you actually need to recover on a daily basis to make it worth your while to work the deposit. Sometimes there is a big difference between what a person says he or she must recover and what a person will accept in order to remain in a deposit. You should be honest with yourself about this. If you need to recover five pennyweight a day, then you should not be production mining in a deposit which is paying only one pennyweight a day, unless you have some reason to believe it is going to improve right away. Also, if five pennyweight a day is your acceptable level, you should discipline yourself to mine the lower-grade gravel on the boundary-edge of a pay-streak if it is paying this much or more, no matter how much more the higher-grade section of the gold deposit is paying.

Some pay-streaks have a richer portion in the center or along one edge, and a lower-grade section throughout the remainder, which still may be high-grade enough to work by your own standards. Yet, you will find yourself much more interested in recovering the gold out of the rich section, because it is more exciting as you uncover all that gold. It takes personal discipline to work all of the acceptable portions of the pay-streak, when only one portion is extremely high-grade. I have seen many deposits (some of them my own) wasted by miners moving forward, dredging only the high-grade, while dumping tailings on the lower grade–but still acceptable–portions of the pay-streak. We all learn through hard-won experience just how valuable pay-streaks are once they are located, and how important it is to production-mine them in a disciplined and orderly manner, wasting as little as possible

There is an old maxim which always seems to be true: If you are looking for easy gold, go where others have already found it, and look beneath the area in which they started laying down their tailings! People get so excited when first discovering a deposit, they usually don’t think much about what they are dumping their tailings on top of until it is far too late!

The main point I have been trying to make here is that sampling really never ends. When you are not in a deposit, you will find yourself sampling to find one. When you find one, if you are wise, you will constantly sample to keep yourself within the boundaries of the deposit. Then, you’ll need to sample again to find another pay-streak in the immediate area once the first one runs out. Sampling basically is your procedure to acquire the necessary perception of where the gold is so you can recover as much as possible for your efforts. This is why you want to be good at it.

Don’t quit!

- Here is where you can buy a sample of natural gold.

- Here is where you can buy Gold Prospecting Equipment & Supplies.

- More About Gold Prospecting

- More Gold Mining Adventures

- Schedule of Events

- Best-selling Books & DVD’s on this Subject

True, it is much easier for us now than it was for them. We have

True, it is much easier for us now than it was for them. We have  While some gold-bearing creeks and rivers tend to have gold values dispersed throughout their entire streambeds, there is generally not enough gold to make a small-scale mining operation payoff very well. Because we are limited as to how much gravel we can process as small-scale miners, we need to find

While some gold-bearing creeks and rivers tend to have gold values dispersed throughout their entire streambeds, there is generally not enough gold to make a small-scale mining operation payoff very well. Because we are limited as to how much gravel we can process as small-scale miners, we need to find

And, if you are not sure if you have given a sample hole everything it deserves, be honest with yourself about it and give it a little more. It takes personal discipline to be a good sampler!

And, if you are not sure if you have given a sample hole everything it deserves, be honest with yourself about it and give it a little more. It takes personal discipline to be a good sampler!

feel the excitement about the prospects of the new season. What is it about spring that gives people so much renewed hope and interest? Even people who failed utterly during seasons past, who considered giving up gold mining forever, seem to be

feel the excitement about the prospects of the new season. What is it about spring that gives people so much renewed hope and interest? Even people who failed utterly during seasons past, who considered giving up gold mining forever, seem to be  There is more to success than

There is more to success than  the basic way you approach mining. Only you can do that. To experience the magic of success in any activity, failure and inability has to be overcome by positive energy and personal discipline. True magic cannot be obtained by forgetting failure or justifying it away.

the basic way you approach mining. Only you can do that. To experience the magic of success in any activity, failure and inability has to be overcome by positive energy and personal discipline. True magic cannot be obtained by forgetting failure or justifying it away. The old man leaned against his shovel and wiped his brow as the hot interior Alaska sun beat down upon him. He was a veteran of the

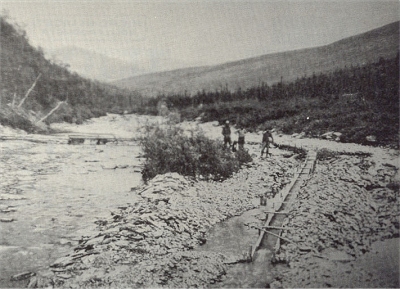

The old man leaned against his shovel and wiped his brow as the hot interior Alaska sun beat down upon him. He was a veteran of the  My first homemade sluice box was built from old photos, some advice (some poor and some good), a few aged pieces of plywood and two-by-fours, wooden slats for riffles and burlap to catch the gold. At sixteen, I had visions of gold, just like any other person would after reading Jack London’s books and other stories about the gold rush. Having been raised in the gold camps of the Circle Mining district in eastern Alaska, I had watched many miners, including my father, extract gold with sluices and gold pans.

My first homemade sluice box was built from old photos, some advice (some poor and some good), a few aged pieces of plywood and two-by-fours, wooden slats for riffles and burlap to catch the gold. At sixteen, I had visions of gold, just like any other person would after reading Jack London’s books and other stories about the gold rush. Having been raised in the gold camps of the Circle Mining district in eastern Alaska, I had watched many miners, including my father, extract gold with sluices and gold pans.