LEARNING BY EXPERIENCE: Hands-on experience is a very important part of The New 49’er program. It is our ongoing group mining programs (along with our abundant property reserves) which distinguish us from other prospecting organizations.  We believe that the future of small-scale prospecting could largely depend upon how effectively we as an industry pull together in a responsible way to meet the challenges which we will face together. Much of this effectiveness and dedication is contingent upon gaining exposure to existing operations which are already effective. This is because, generally, the more skilled you are as a gold prospector, the better your chances of realizing your expectations, ambitions, and goals. Moreover, it is generally true that if you are successful, you radiate your success to others and our entire industry flourishes and grows.

We believe that the future of small-scale prospecting could largely depend upon how effectively we as an industry pull together in a responsible way to meet the challenges which we will face together. Much of this effectiveness and dedication is contingent upon gaining exposure to existing operations which are already effective. This is because, generally, the more skilled you are as a gold prospector, the better your chances of realizing your expectations, ambitions, and goals. Moreover, it is generally true that if you are successful, you radiate your success to others and our entire industry flourishes and grows.

Certainly, proven mining property is also an important key. But gaining exposure to effective mining and prospecting techniques by actually doing it with others who are more experienced is vital since a less-inexperienced person can do poorly even on very good mining property. Most of our programs consist of direct hands-on experience in the field, where you can gain direct exposure on how to do it right through group mining projects where all the gold is split amongst all of the participants.

Yearly, we are proving that our group mining ventures help create successful, invigorated prospectors who are excellent examples to others. Others then become interested, participate in group projects, become successful, and our organization and our industry prospers and expands.

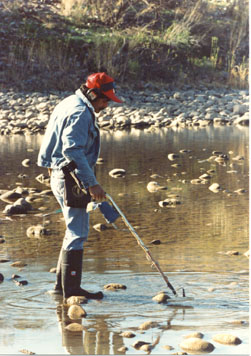

ORGANIZED GROUP PROSPECTING PROJECTS OUT OF THE WATER: We sponsor weekend group prospecting projects for members on a continual basis between June and October. These valuable projects allow participants direct exposure to prospecting for gold through panning, motorized sluicing, vacuum-mining, sampling techniques, and important information about how and where to find gold on our properties. These projects consist of an exciting, fun-filled, and information-packed outing along the Klamath or Salmon Rivers. This is a interesting and (always) exciting group surface prospecting operation (out of the water) where participants each receive an equal share of the gold recovered.

- Schedule of Events

- Booming” in the Mega-Hole!

- Members Strike Gold & Adventure on New 49’er Properties!

- Recovering High-grade gold Along the Klamath River!

- Member Experiences

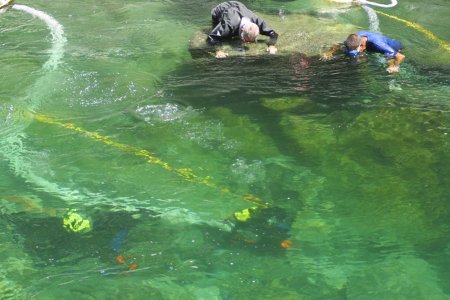

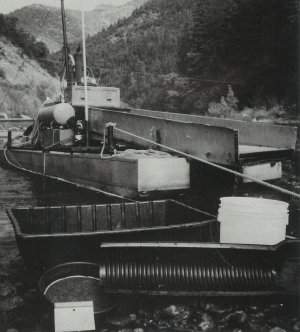

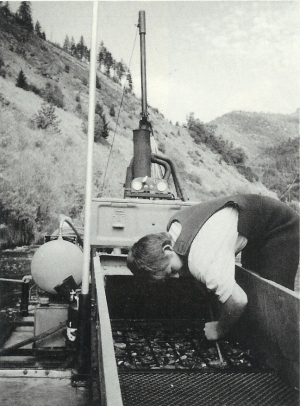

WEEK-LONG GROUP PROSPECTING PROJECTS: Experienced gold miner and New 49’er founder, Dave McCracken, personally supervises week-long group prospecting projects during the mining season, where each participant shares in the work to be done and the gold that is recovered. While the primary purpose of these projects are to prospect and mine for high-grade gold deposits, these organized prospecting programs are an excellent way for members and guests to gain valuable prospecting experience and have a fantastic outdoor adventure at the same time. No prior experience is necessary. Some group projects are with the use of motorized sluices and vacuum-mining machines (prospecting out of the water). Other mining projects are with dredges.

Dave often uses rubber rafts or boats to carry fellow participants into otherwise inaccessible gold-bearing areas along the Klamath River. These areas are where few prospectors have gone before, so the potential for awesome success is higher than normal.

The New 49’ers provide all of the dredges, motorized sluicing equipment and boats used in these projects. Participants will need to have their own wet-suits (for those who will dredge) or other protective clothing and footwear, a dive mask and transportation. Participants provide their own lodging and nourishment.

The New 49’ers provide all of the dredges, motorized sluicing equipment and boats used in these projects. Participants will need to have their own wet-suits (for those who will dredge) or other protective clothing and footwear, a dive mask and transportation. Participants provide their own lodging and nourishment.

Please contact our office or click here for more details, rates and the schedule of any upcoming group prospecting projects.

Week-long group projects are limited to a certain number of paying participants. Scheduling in advance is strongly advised to ensure a position on any specific week-long project. A nonrefundable deposit is necessary to secure your position in advance for a project.

A schedule of this year’s Group Projects and participation costs can be found at this Schedule link, and is also freely available by contacting our office. Please phone us at 530-493-2012 to request a copy.

By Dave McCracken

“When lots of gold starts coming into play, everyone gets excited and in a hurry!”

At the beginning of a recent season, my partners and I were sampling a promising section of our properties along the Klamath River for new pay-streaks. We had dredged several holes and were onto a deposit. Since we did not know if it was high-grade enough for us to work, we were dredging more holes up and down the deposit to get a better idea. On the fourth or fifth test hole, we uncovered a section of bedrock which had gold lying all over it; it was truly rich!

Something always happens in the dredge hole when dredgers start uncovering lots of gold! It does not matter how professional or experienced the operators are. When lots of gold starts coming into play, everyone gets excited and in a hurry. And it was no different on this occasion.

There was a pretty good sized boulder in front of us, slightly up in the streambed material. It was too large for one of us to move. But we thought both of us, working together, could probably roll it to the rear of our hole. Hurriedly, because we were anxious to see more gold on the bedrock, we made room behind us for the boulder by throwing a bunch of smaller rocks and cobbles further behind. Then we climbed upstream of that big rock and gave it a shove. The rock moved more-easily than we thought and slammed into the hole—right on top of my airline!

We use extra heavy-duty airline, the kind that does not kink under normal working conditions. I have tossed cobbles onto it hundreds or thousands of times; I have rolled boulders over it; and I have never had an instance where the airline was damaged in any visible way. That is, until this time.

We use extra heavy-duty airline, the kind that does not kink under normal working conditions. I have tossed cobbles onto it hundreds or thousands of times; I have rolled boulders over it; and I have never had an instance where the airline was damaged in any visible way. That is, until this time.

As soon as the boulder stopped moving, I lost all my air supply. That is when I realized the boulder had pinned my airline underneath. I was already winded from the exertion of shoving on the boulder. So quickly, my partner Rob and I put our shoulders against the boulder, propped it up, and I pulled my airline out just far enough to see that it was split almost in half. We set the boulder down to deal with this new problem, but the boulder still had my airline trapped from behind.

These kinds of emergencies unfold very quickly when they happen underwater. One moment everything is fine. And the next moment, your life is hanging in the balance of what you do! I had a similar event once where I got pinned to the bottom by a slab of bedrock that fell on top of me from the side of the river.

First I thought I might be able to get air by holding the airline together and compressing it in my hand. This did not work and I was really starting to hurt for air; the second stage of panic was just starting in. What is the second stage of panic? It’s when you are on the verge of a psychotic break!

I looked to Rob and signaled him to cut my weight belts loose. We were working in fast water and I was using a second 25-pound belt to keep me in the hole. Instead, Rob handed me his regulator. Good idea, I had not even thought of that! So I took five long, deep breaths from Rob’s regulator. I would have taken more, but he had that “growing worried” look in his eye. The air was a big help, but far from satisfying; my body was demanding more.

However, the air did reduce my emotional state down to first stage panic—which is non-careful, frantic action. I signaled for Rob to release my belts again. The reason I was asking Rob to remove them is that a face mask prevents a diver from being able to see his or her own belt, so it is much easier for a second diver to release them.

I had one heavy belt which carried about 60-pounds of lead. And my second belt, with about 25-pounds, was connected to my airline. Rob released my heavy belt, not seeing that the airline was still connected to me.

This was all happening very fast. Rob was having panic problems of his own, because he was desperate for air while I was breathing off his regulator. When I handed him his regulator back, he was having trouble removing the water from it. So Rob cut his own weights loose and was gone with his own airline. With my heavy belt gone, I floated up into the current and reached the end of my airline (which was still stuck under the boulder), stuck about six feet from the surface. I immediately reached second stage panic; I was dying for air!

We use a boom on the front of our production dredges to help support the suction hose. A cable extends from the boom down to the suction hose. Looking up from my suspended position, I realized I was in reach of the boom cable. I had already frantically tried to find the quick-release buckle on my weight belt. But the belt had shifted around somehow; and with my heavy rubber gloves on, and in my panicked state of hurriedness, I could not find the buckle. I snapped into third stage panic, grabbed onto the cable and started pulling myself to the surface with everything I had. It was an inch at a time.

Finally, when my face was about one foot from the surface, the airline would no longer give. So close, but so far! In a last ditch adrenaline pull, I managed to get my mouth just above the water’s surface; I got a breath of air and water. I did it a few more times. Then I pulled my glove off the right hand, stuck it under my left armpit (no use in throwing away a good right-handed glove), and reached around to release the weight belt. It fell away and I was quickly on top of the dredge. Rob was up there hoping I was going to make it.

That one was close!

While I was catching my breath on the surface, without any delay, I asked Rob to go down and recover our belts and my air line. We repaired the line with some parts in our tool box, fueled up the dredge, and went right back down to finish the sample hole. I immediately went back down to finish the dive because I believe it is important to get back on the horse that throws you without delay, especially when you are feeling emotional trauma from a harrowing experience.

The pay-streak turned out to be a good, rich one!

I learned a few valuable safety lessons that day—the primary one being to not roll heavy rocks across my airline. This means knowing exactly where my airline is, along with everyone else’s in the hole, at the time when boulders are being moved.

Here are a few other pointers we have learned about airlines from our experience: Stay aware of where your airline is. Do not allow it to get wrapped and tangled around objects, the suction hose, tangled with other divers’ airlines. Immediately untangle your airline if it does get caught up in any way that might prevent you from getting quickly to the surface or the stream bank in an emergency.

Here are a few other pointers we have learned about airlines from our experience: Stay aware of where your airline is. Do not allow it to get wrapped and tangled around objects, the suction hose, tangled with other divers’ airlines. Immediately untangle your airline if it does get caught up in any way that might prevent you from getting quickly to the surface or the stream bank in an emergency.

I am a true believer in extra heavy-duty, non-kinking airline. Not only is it non-kinking, but it is also a safety line. We run several wraps around the frame of our dredge before plugging our airlines into the air system. This way, if we need to pull ourselves up the airline in an emergency, we are not pulling directly against brass fittings.

Airlines generally float when being used under normal circumstances. This means you have to watch out that yours does not get tangled around the underside of your dredge. Airlines usually sink to the bottom when they are being used in conjunction with a hot water system, which pumps hot water down to the dredger through a second line that is fastened to the airline. In this case, you have to watch what the airline might get tangled around on the bottom of the river. And, spoken from hard-won experience, you have to be careful not to roll boulders on top of it. You also have to watch that you do not bury your air line with cobbles being thrown behind your dredge hole.

Avoid using longer airlines than are necessary. Ten or twenty feet longer than the suction hose is just fine. Longer airlines tend to get caught on more objects and set up more drag in the current.

When we are working in fast current, and the heavy drag on the airline is a problem, we pull our airlines up onto the back-side of the dredge hole and put a cobble on top to hold it there against the fast water. The cobble must be large enough to hold the airline down, but not so large that you cannot jerk it free in an emergency rush for the surface or stream bank.

We always untangle and unwrap our airlines on our way to the surface at the end of every dive. This gives us a free airline to coil up on deck at the end of the day, or to use again at the beginning of the next dive.

And we always replace or repair a damaged or defective airline without delay. Murphy (as in Murphy’s Law) lurks behind every corner! There are so many details to get right in a dredging operation of any size. There are many things which can possibly go wrong. We try to do everything right to avoid problems. But one thing we should never get lazy about is maintenance action on our air systems. If it even looks like it could be a problem, fix it now! And use quality repairs! Clamping copper tubing between two pieces of airline is not the way to do it!

And we always replace or repair a damaged or defective airline without delay. Murphy (as in Murphy’s Law) lurks behind every corner! There are so many details to get right in a dredging operation of any size. There are many things which can possibly go wrong. We try to do everything right to avoid problems. But one thing we should never get lazy about is maintenance action on our air systems. If it even looks like it could be a problem, fix it now! And use quality repairs! Clamping copper tubing between two pieces of airline is not the way to do it!

All in all, I believe safety is a personal matter. This is all about having the right approach in the first place. Different people have different levels of ability doing different things. While one person may have trouble walking across the street without encountering grave personal danger, another person can stay out of personal danger while pursuing hang-gliding or sky-diving activities.

Still, it is true that the more adventuresome the activity, the less margin there is for error. And in adventuresome activities, when things do go wrong, it often turns into a life-threatening emergency. So it is very important to cross all your “T’s” and dot all your “I’s” when it comes to your air system.

- Here is where you can buy a sample of natural gold.

- Here is where you can buy Gold Prospecting Equipment & Supplies.

- Schedule of Events

- More About Suction Dredging

- More Gold Mining Adventures

- Books & Videos by this Author

By Dave McCracken

Showing people how to find high-grade gold has as much to do with developing the proper focus as it does with passing along helpful information.

Running a successful mining operation is one thing. Helping someone else to be able to run a successful operation is something else altogether. During the past several years, we have worked with hundreds of people in basic gold mining techniques and dozens of men and women in commercial underwater mining procedures. We have also had the opportunity to observe many others conduct their own mining operations in Africa, South and Central America, Alaska, Canada, Indonesia, Cambodia, Viet Nam, Madagascar and along the rivers of Northern California. Working with the theories and procedures, you are also working with the person’s ability, or lack of ability, to apply the principles.

Running a successful mining operation is one thing. Helping someone else to be able to run a successful operation is something else altogether. During the past several years, we have worked with hundreds of people in basic gold mining techniques and dozens of men and women in commercial underwater mining procedures. We have also had the opportunity to observe many others conduct their own mining operations in Africa, South and Central America, Alaska, Canada, Indonesia, Cambodia, Viet Nam, Madagascar and along the rivers of Northern California. Working with the theories and procedures, you are also working with the person’s ability, or lack of ability, to apply the principles.

A number of years ago, it became apparent that future growth and success of my own commercial activities in this field would depend, in part, on our ability to guide others in successful gold mining procedures–not just in theory, but in actual application. As part of our effort to improve our capabilities, I have personally devoted quite a lot of effort trying to understand why some people (a healthy percentage, actually) cannot seem to acquire the ability of practical application of successful mining and sampling procedures–even though they apparently understand all of the theory behind them.

I personally know a fair number of successful gold miners; some who we worked with and some who learned on their own. Some are successful on a smaller-scale. Some mine gold to support themselves and their families.

I personally know a fair number of successful gold miners; some who we worked with and some who learned on their own. Some are successful on a smaller-scale. Some mine gold to support themselves and their families.

I also know a fair number of rather unsuccessful miners, some who we have given some help to and others who would not accept help if their lives depended upon it.

Unquestionably, there is a distinct difference between successful miners, partially successful miners, and those who are completely unsuccessful. A fundamental way to explain the differences is with the concept of wavelengths.

Consider the idea that each person is similar to an electronic frequency radio tuner, and that the universe consists of an infinity of possible frequencies which can be tuned in. I propose a theory that successful gold miners have themselves more finely tuned on a particular frequency than those who are not so successful.

Why is it that sometimes you try and tell a person how to do something better, when the person obviously does not know how to do it properly–but the person won’t listen, won’t understand, wants to disagree, becomes suspicious of you, won’t accept help or rejects your information? Helpful information is coming the person’s way, but the person is not tuned to the frequency to receive and utilize the signal. In fact, he may be tuned to a rejection-frequency.

One of the primary common denominators I recognize being present in successful miners alike is a never-ending drive, or hunger, or urge to get on and stay on the pay-streak during their mining activities. You can actually SEE this drive or hunger as part of their beingness. This urge is similar to an entrepreneur looking for a good investment opportunity, or a businessman wanting to close a profitable deal, or a musician trying to create an exceptional melody, or the drive an athlete has to win a race.

One of the primary common denominators I recognize being present in successful miners alike is a never-ending drive, or hunger, or urge to get on and stay on the pay-streak during their mining activities. You can actually SEE this drive or hunger as part of their beingness. This urge is similar to an entrepreneur looking for a good investment opportunity, or a businessman wanting to close a profitable deal, or a musician trying to create an exceptional melody, or the drive an athlete has to win a race.

All gold miners WANT to be successful and find lots of gold. The difference is that successful miners CREATE success by learning how to do it, by hustling around to find the best opportunities, and by actually making success happen. The best simply have themselves more finely tuned and focused on the desired wavelength!

Unsuccessful people often allow themselves to be diverted off the wavelength by little losses, or unknowns, along the way–or by little decisions: “I can’t do it,” “I don’t know,” “I’m not good enough,” “It’s too hard, etc.”

As an example, I can look back to my own involvement with gymnastics in high school. I was moderately successful–enough to become co-captain of our team during my senior year. But there were others we competed against who were far better than me.

I look at these kids today who are near perfection and realize that I was never really even in the league. Why? At the time I felt that those who were better had more inherent gymnastics ability than I did. But the truth is that they were more focused into advanced-gymnastics perfection than I was. This made them better gymnasts. There is no rightness or wrongness in this; you end up receiving exactly what you focus upon.

Someone more sympathetic might say that I lacked the proper coaching. And I’m sure thaey are right that exteriour environmental factors play a part in this. But even the best coach cannot help a person who insists upon setting fixed personal limitations.

My ex wife’s son, Derek Parra, wanted to be the world’s fastest speed roller-skater. He finished high school a half year early with honors; and with no money or financial support, moved to Florida where he could be near a world-class coach. He made the world skating team in his first year and took a gold medal at the World Games. When he realized that roller skating would not make it into the Olympic games during his time, he made the very difficult move of switching from the top of the roller world to the lower-end of ice skating. But within several years, he worked his way up to take gold and silver metals in the Olympics. Now that is focus far beyond coaching!!

I’m focused on being the world’s best underwater mining specialist–and on helping others, also, to be very good at it.

I’m focused on being the world’s best underwater mining specialist–and on helping others, also, to be very good at it.

In working at this, I am finding that showing people how to do it only partially has to do with passing along helpful information. It actually seems more to do with developing the proper focus. This is why hands-on experience is so enormously valuable in any field.

If I wanted to be an expert at computer programming, I would spend the necessary time learning the basics and then devote myself, at any cost, for a year or two working under the guidance of a proven master. Why? Because the Master is riding directly on the frequency of success in this endeavor. His tuner is locked onto the precise channel I am searching for. My time is valuable. Why spend ten years trying to attain the successful frequency when I can learn it from a master in one tenth the time?

There is a big difference between having an understanding of the theory of mining, and having the ability to apply knowledge perfectly to obtain the optimum result.

The following is a short list of some of the differences I have noticed between successful and unsuccessful people — both inside and outside of the field of gold mining:

Receiving Help: Successful people willingly and gladly accept help wherever it is needed. They also tend to be freely willing to extend a helping hand to others who are in need. Unsuccessful people have a perverted idea of help, sometimes expecting others to do the job for them— and then being suspicious of the helpers, wondering what their malicious intent might be. They might refuse help to others altogether–or help somebody so they can gain leverage over them. Some refuse help from others, feeling they don’t deserve it–or sometimes feel that to accept help would be admitting failure. Such people are almost impossible to help.

Handling Data and Knowledge: Successful people, and those on their way towards success, tend to be hungry for new and more information which they can utilize to boost themselves towards accomplishment. Each piece of useful information is learned with care, sorted properly as to its importance and usefulness, and held in standby as another tool in a never-ending drive for success.

Unsuccessful people often can be spotted trying to be “experts,” trying to “remember” bits and pieces of information to prove to others they know what they are talking about.

Most often, because of lack of true focus on accomplishing a goal, the unsuccessful person also has an inability to evaluate the different degrees of importance of information. For example, such a person might not understand (as far as his ability to apply knowledge in the gold-finding field), that the datum “Gold is six times heavier than gravel” is substantially-more important than “Gold is an excellent conductor of electricity.” An electrician would see the second datum as more important. A successful miner knows the first datum is more important to him, because it is a far more useful tool, by today’s methods, in finding where gold deposits are located.

Focus and Intention: You cannot be an expert at everything. Successful people choose the areas in which they want to do well and focus their attention and intention (getting on the frequency) at becoming good in those areas.

Such people are a breeze to train. If you are not telling them how to do it, they are figuring it out for themselves. Unsuccessful people tend to focus either too narrowly–where they cannot evaluate importance, or too broadly — where they don’t have the necessary attention or intention to follow through. Often, unsuccessful people tend to focus on failure, problems, barriers, or resentments, rather than focus on what needs to be done to get on with progress.

Handling setbacks: There is no one who hates a failure more than a predominantly-successful person! However, many very valuable lessons are learned the hard way by doing things less than perfect the first few attempts–especially when treading on new territory. Successful people generally have enough personal drive to learn from mistakes and keep pushing forward even though there may be some pain and discomfort during the process.

Unsuccessful people tend to collapse because of setbacks, resulting in the primary focus staying on the problems, rather than achievement of the goal of success. After a time, small setbacks add up to a major failure – which eventually results in the person giving up altogether on the endeavor. We see this quite regularly in gold mining, when a person is in the prospecting phase and doesn’t find a pay-streak right away.

The successful person, even while hurt during setbacks, recovers from the loss, re-focuses on the goal, throws off the negative energy, feeds on the gains, and keeps moving forward as best he or she can.

Dealing With Success: Many unsuccessful people don’t do well because they do not feel they deserve to. But most often you will find them consciously blaming others for their problems and failures. Lack of responsibility for one’s self and one’s actions goes hand in hand with failure. Along with this, you will find unsuccessful people constantly upset and resentful at the success of others who are working more energetically towards accomplishment of life’s goals.

I can often tell who my true friends are not; those who are disappointed every time I get into an excellent pay-streak!

Generally, successful miners are happy to see others do well–unless the other happens to be someone who is first to a person’s secret hot spot. A successful miner might be a bit envious of another’s gold find–but probably not resentful. And if anything, he is most likely to spur himself on to work harder to find a better hot spot of his own.

Personal Integrity: This is most important, so I left it for last. What kind of person am I? Certainly there will not be much personal improvement if we are not willing to look at what we are, and be honest with ourselves about what we see.

Don’t like what you see? Change it–don’t bury it! Everyone is somewhere on the scale from heaven to hell. The direction upward is through personal honesty, integrity and willingness to improve those things you see in yourself which you are not pleased with. The way downward is to not look, to hide from yourself, and to be ruled by those things inside yourself that you don’t like…

Cheaters never really win! Because, by definition, a person who feels he must cheat to win is below the level of actually playing the game in the first place. Therefore, cheaters are really living in a game of their own–not truly in communication with those around them. Giving up your true self, your real happiness and your personal well-being, is a huge price to pay for having some temporary material belongings.

There are a lot of unhappy people around who act like they are happy. Look around. What do you think their problem is? However, even their game is not over. Wherever a person finds him or herself, the road continues in two directions.

Successful people win their games by focusing themselves towards accomplishment within the rules of the game. Don’t like the rules? Do something effective to bring about agreement to have the rules changed. Winning the game by the rules brings great satisfaction, and successful people are willing to put out the necessary effort to gain each step along the way. Sure, it’s always a bit more difficult to not take the unethical short cuts which present themselves. But real progress is built upon a solid foundation of the ability to accomplish.

Successful people win their games by focusing themselves towards accomplishment within the rules of the game. Don’t like the rules? Do something effective to bring about agreement to have the rules changed. Winning the game by the rules brings great satisfaction, and successful people are willing to put out the necessary effort to gain each step along the way. Sure, it’s always a bit more difficult to not take the unethical short cuts which present themselves. But real progress is built upon a solid foundation of the ability to accomplish.

Unsuccessful people can often be found looking for the short cuts, the get-rich-quick schemes, or are willing to bend the rules–or cheat outright to win the game the easy way. Ultimately, such gains are only temporary because they are not built upon a foundation of the ability to create or perform–only the ability to take advantage of shortcuts.

Personal integrity is most important, because a person’s ultimate success in life, or mining, or any other endeavor, starts from his or her own source-point, wherever that may be. A person low in personal integrity may not allow himself to succeed, regardless of how hard we try and train him! The desire to be a successful gold miner, computer programmer, athlete, or good husband, is an impulse that begins and ends with the individual. And if the person isn’t being honest with himself, who he is, what he is, what he is doing, what principle he stands for, and where he truly wants to go, then it’s more than likely the person will not have the necessary drive to become truly successful at mining.

So you can see, there is more to helping a person to become successful than just showing him or her how to do it right. Sometimes, you also have to help get the person onto the success-frequency. And when you have accomplished this, then you have struck real pay-dirt.

- Here is where you can buy a sample of natural gold.

- Here is where you can buy Gold Prospecting Equipment & Supplies.

- More gold mining adventures

- More about suction dredging

- More about how to prospect for gold

- Schedule of upcoming events

- Books and Videos by Dave McCracken

By Dave McCracken

When the gold starts being trapped further down the length of the box, it is definitely time to clean up your box!

Some miners like to clean up their sluice boxes after every hour of operation. Some prefer to do clean up at the end of the day. Others will go for days at a time before cleaning up. This is a matter of preference and seldom has much to do with the actual needs of the sluice box. Some of the large-scale operations, which ran during the early 1900’s used to allow the lower two-thirds of their boxes to run for months at a stretch without cleaning them up, and without very much concern about losing gold. However, it is true that sluice boxes were longer in those days.

There is a method of determining when a sluice box needs to be cleaned up to keep it operating at its utmost efficiency. If the majority of gold is catching in the upper third section of the sluice box, then the recovery system is working well.

After a sluice box has been run for an extended period of time without being cleaned, the riffles will have concentrated a large amount of heavy materials behind them. Sometimes a lot of heavy concentrated material in a sluice box will affect the efficiency of the riffles’ gold recovery. This is not always the case; it depends on a number of different factors, like the size and shape of the gold, the size and type of riffles being used and how they are set up in the box.

The true test of when a set of riffles is losing its efficiency because of being loaded down with heavy concentrates is when the gold starts being trapped further down the length of the box than where you are comfortable seeing it. When this occurs, it is definitely time to clean up your box.

Otherwise, clean them whenever you like.

Expanded metal riffles, being short, will tend to load up with heavy black sands faster than the larger types of riffles. But shorter riffles generally concentrate fine gold better than deeper riffles.

A large, visible amount of black sand being present is not necessarily a sign that you are losing gold. Gold is four times heavier than black sand. In some cases, the black sand will have little effect on gold recovery. Again, it depends on how the system is set up, the type of material being run, the purity (and therefore weight) and shape of the gold, as well as other factors.

The best way to evaluate your recovery system is by direct observation of where the gold is being trapped.

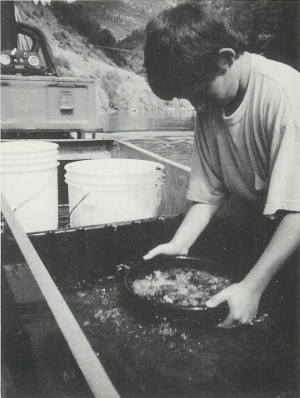

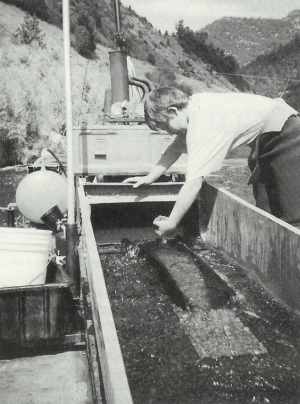

BY SAMUEL T. LONG

No matter what the size or nature of our mining operations, we all have one common procedure to deal with—the cleaning up of our concentrates. Sometimes, the process of separating the gold from the other sand and gravel is a tedious task. But, there is a way to make it relatively quick and easy.

No matter what the size or nature of our mining operations, we all have one common procedure to deal with—the cleaning up of our concentrates. Sometimes, the process of separating the gold from the other sand and gravel is a tedious task. But, there is a way to make it relatively quick and easy.

This final step, before the gold is totally isolated, is of no less importance than the prior steps used to recover the gold laden concentrates themselves. Many times, in a mining operation, much thought and energy have been used to successfully reach the clean-up stage, only to squander the last remaining hours of the afternoon or early evening on an inappropriate and/or wasteful system of final gold clean-up. In fact, some operations take so long to complete this stage that they’re not started until the next day!

Final clean-up of concentrates should take minutes, not hours. If you can’t go from sluice box concentrates to gold in a bottle in less than an hour, your technique needs to be examined, then streamlined.

We all know the direct relationship between time, effectiveness, and gold. Its no secret, for instance in dredging, that the more time you spend during the day pumping gravel, the more gold you’ll have at the end of the day. All the effort you spend on plug-ups, throwing and re-throwing rocks, moving the dredge, winching unnecessary boulders, and all the other odds and ends “Murphy” continually throws at you, essentially steals valuable time from operating the suction nozzle. This, in turn, logically lessens the amount of gold in your box on any given day. So, an important aspect of successful gold production is efficiency. Isolated efficiency used mainly during diving time is not enough. Productivity, in every aspect of your over-all mining operation, is vital for success. Clean-up of concentrates is no exception.

Before we go any further, lets look at a few clean-up methods that, for one reason or another, don’t prove to be satisfactory. Maybe yours is in this short list:

1. Panning: Simple, direct, and economical. But time consuming. It works after a fashion, but obviously a prospector’s sampling tool, at best. If you do use a pan to do final clean-up, you will find the process goes much better if you first classify your concentrates through a series of mesh-screens and pan each size-fraction separately.

2. The Tweezer Method: Again—simple, direct, economical and EXTREMELY time consuming. Actually, it works great for the first eight or ten pieces of gold you pick up. Its the next two hundred pieces, or 20,000 pieces, and your unasked for double vision, that puts the “kibosh” to this method. This method is unworkable as soon as you begin finding more than just gold traces in your sampling.

3. Spiral Gold Wheels: Here’s the backbone of many clean-up operations. Wheels are basically good tools at a moderate price, but can fall flat on their face when it comes to efficient use of time. Its almost impossible to classify, run, and re-run concentrates through any wheel and still break the one hour target. If you use a wheel, don’t throw away the final concentrates that remain in the bottom-edge of the wheel after all the gold has climbed out. Because there always seem to be pieces of gold that will not climb out! Save those concentrates for another day…

4. Shaker Tables: Very effective for fixed commercial operations. But generally too bulky to support portable sampling programs. They are also quite expensive. Unless you already own one, you can still be effective without it.

This is not to say that there is only one correct way to clean-up; and if you’re not doing it that way, that you’re doing it wrong. This is just to show you a fairly quick, cost-effective, simple way to separate gold from your sluice box concentrates; a method by which you can cut your clean-up time from two hours to less than one hour with only the addition of a few simple tools and techniques:

1. A very important part of any efficient clean-up method is what percentage of the sluice that you are cleaning up. No matter what size sluice you have, or how it came from the factory, it is imperative that you re-design it so it’s possible to clean the top 20-25% of it without disturbing the rest of the sluice.

We call this the “high-grader.” Because it is extremely heavy, eighty percent or more of the gold will regularly be in the top 20% of the sluice box. Given this fact, there’s no need to spend extra time and effort cleaning the entire box each time you clean-up. All that extra time could be much-more effectively invested in the sampling or production-phases of your program! On an average, clean the top section every day, the middle section every two weeks and the back section every month or so. You have to be flexible about this, depending upon how rich the gravel is that you are mining. This saves a lot of work while still retaining all the gold. Design your sluice in individual sections and clean them on a staggered basis.

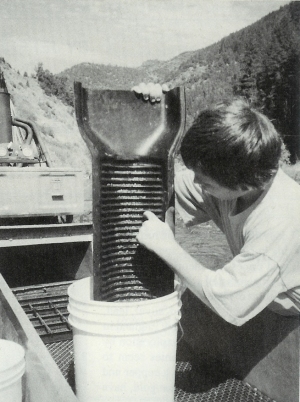

2. Remove the riffles and miners moss with concentrates from the top section. Rinse the riffles and thoroughly wash out the miners moss into a utility tub. A flat kitchen-counter scraper works well to clean the bottom of the sluice. Immediately replace the miners moss and riffles.

3. Using another utility tub, transfer the concentrates from one to another via a 4-mesh classifying screen.

Check the top of the screen for nuggets before discarding the over-sized material. You never know when one will appear. This 4-mesh classification should cut the amount of concentrates by around fifty percent. Dump the classified material into a five gallon bucket. Now you have gone from five gallons of concentrates to two in only about ten minutes.

4. Start the dredge and run it at low idle. Set the black plastic mini sluice (or the Le’ Trap plastic clean-up sluice) in the top of the sluice. The moving water will hold it in place. Note here that it is counter productive to use a longer plastic sluice instead of a small one. That’s because you’ll end up with twice as much material, but no more gold. The object of this step is to get the material down to a workable amount for final clean-up. If you use too large a mini sluice, it will take another step to reach this proper volume. While it is probably not necessary, we like to lace the one-foot square of miners moss under the tail of the mini sluice in such a manner that all material washing out must travel over the moss. This is to catch any fine flakes of gold that may be washed out of the sluice. However, because the process is usually done inside the sluice box of your bigger recovery system, there is little chance any gold can be lost anyway.

5. Carefully drop the concentrates a handful at a time into the top of the mini sluice.

Adjust the water flow via the throttle so that the concentrates are gently carried away while leaving the gold in the top few riffles. We have found that this step goes much quicker and simpler than using a gold wheel or gold pan. The process is so efficient, we have found that running the concentrates through the mini-sluice twice is a waste of time.

6. At this point you’ve only spent about twenty minutes and you’re more than half-way to having completely separated the gold from the rest of the concentrates. Next, rinse out the square of miners moss and the contents of the mini sluice into a bucket.

Notice there is only a fraction of a pan’s worth of concentrates remaining. These can be dried out in a small, steal gold pan over an open flame (outside in a well-ventilated area), screened, and carefully separated with a gentle blowing process on paper. The best demonstration I have ever seen of this final process of separation can be found in Dave McCracken’s video, “Successful Gold Dredging Made Easy.” Who said clean-up had to be tedious and time-consuming using expensive tools? So far, we haven’t even left the river and we’ve gone from nearly five gallons of concentrates to less than a cup in only twenty-to-thirty minutes. This easy technique, coupled with the dry final separation, is all you need to make your operation more enjoyable and successful.

Expertise in clean-up demands an approach that will deliver all of the gold in your concentrates in less than an hour. Anything longer than this is a waste of time and energy which definitely subtracts from your over-all mining success and enjoyment. As you know, a chain is only as strong as its weakest link. While streamlining clean-up may not drastically improve total gold quantity, it is surely a step in the right direction. Gained insight concerning your clean-up methods may reveal ineffectiveness in other areas as well; the sum of which very well could mean the distinct difference between success and failure in your operation.

By Dave McCracken

Raw gold creates an impulse inside of you that makes you want to possess it, to own it for yourself, to hoard it away, to treasure it as your own!

Not too long ago, while dredging with partners on the Klamath River in northern California, we located a very rich deposit, sometimes recovering as much as 24 ounces of gold per day. This was one of the best gold deposits I personally have ever located!

While some people are skeptical about the subject, the condition of “gold fever” really does exist. I know, because I have felt the heat and confusion on more than one occasion. I have written in the past that gold fever affects different people in different ways, depending upon the basic nature of their/your personalities. How much gold that is being uncovered also can determine the degree to which gold fever strikes. Some people get excited over recovering just a few flakes! What would happen if they uncovered untold riches out of a bonanza deposit; how would these same people react?

When my partners and I uncovered this very rich deposit, we started by finding about two ounces during the first 30 minutes of sampling. Because it looked so good, we decided to drop back on the pay-streak several hundred feet and dredge another sample hole. We recovered a pound of gold the first day we uncovered bedrock. There were pockets of gold deep enough and big enough that we stirred our fingers in it! We undoubtedly could have doubled our production if we had chosen to dredge efficiently, rather than spend most of our time googooling around together on the bottom, screaming at the top of our lungs, patting each other on the back, and uncovering the gold as slowly as possible to prolong the incredible excitement of uncovering a real treasure.

at the top of our lungs, patting each other on the back, and uncovering the gold as slowly as possible to prolong the incredible excitement of uncovering a real treasure.

After all, in the end the gold gets traded for money and spent or locked away. And all you have left is the memory of having found it. That is a memory I personally will never forget. It is a memory of an adventure that few people on this planet ever get a chance to experience. It is an experience that gets into your blood, goes directly to your heart and soul, and gives you a case of gold fever that will probably never be cured!

I have heard people, after locating rich deposits, express the wish that they did not have partners with whom they had to share. For me, I am really glad I had partners to share this experience with. Because the experience was so powerful, with so much generation of emotional energy, that it is almost impossible to express it to others who were not there.

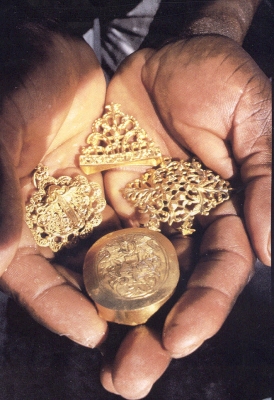

More recently, while consulting in Central America, I had an opportunity to get my first look at real gold treasure! I have spent some time looking for it during the past and spent a lot of time thinking about being in the big treasure hunting game, but this was my first chance to see the real thing as it had come out of the ground. Wow!!

I saw gold and jade artifacts which had been created five, maybe six, centuries ago by people who had not even discovered the wheel! Artifacts so rich in detail, beauty and antiquity that they made my heart pound so hard that I could actually hear it. My body-heat came up enough to run sweat down my back. And my emotions energized to the maximum limit just at the thought of owning such things. No gold deposit ever affected me in this way!

I saw gold and jade artifacts which had been created five, maybe six, centuries ago by people who had not even discovered the wheel! Artifacts so rich in detail, beauty and antiquity that they made my heart pound so hard that I could actually hear it. My body-heat came up enough to run sweat down my back. And my emotions energized to the maximum limit just at the thought of owning such things. No gold deposit ever affected me in this way!

I am told this is called “treasure fever”.

Just like many people who get into gold mining, but never experience a really significant gold deposit, I think perhaps a lot of people get into treasure hunting, but never get a chance to really experience “treasure fever” the way it can really be. It is one thing to think about it, speculate over it, plan on it, and experience it on a subjective level. It is entirely another thing to confront priceless treasure head on, to find it unexpectedly—even when you were planning on it. Then you have to deal with the reality of having uncovered incredible riches.

There is something excitingly-beautiful about the aesthetic wave-length of gold as you locate it in its natural from. It creates an impulse inside of you that makes you want to possess it, to own it for yourself, to hoard it away, to treasure it as your own.

But finding gold which has been refined, perfected and crafted into artistic, beautiful, rich artifacts which were valued and hoarded and lost by people long ago, adds a value of antiquity which intensifies the personal emotional desire to keep the pieces for yourself. This is treasure fever!

I sympathize for treasure hunters or gold prospectors who are not prepared for it, who have not organized their program well, and who are (un)lucky enough to stumble upon real treasure!

I say “lucky,” because most treasure hunters today who find really significant treasures are very well organized, utilize modern equipment, and follow proven techniques. They generally are prepared for treasure when they find it. But, even the most successful and experienced treasure hunters will readily admit that they generally were not prepared for the amount of confusion and greed which resulted from uncovering real treasure!

Gold and treasure will test your personal integrity in a serious way!

While treasure fever, or gold fever, can have many negative connotations, it can also have a very positive affect upon people. Treasure fever adds spice to life, gives you purpose and makes life more interesting.

As gold prospectors, we actually experience the adventures most others only touch on lightly by watching the television!

- Here is where you can buy a sample of natural gold.

- Here is where you can buy a basic gold prospecting kit.

- More About Gold Prospecting

- More Gold Mining Adventures

- Schedule of Events

- Best-selling Books & DVD’s on this Subject

Most intermediate and larger-sized gold dredges come with built-in hookah-air systems. These attach to the same engine that powers the water pump. As demonstrated in the following video segment, air for breathing underwater is generated by an air compressor, passes down through an air line, and provides air to a diver through a regulator, similar to what is used by SCUBA divers:

Most intermediate and larger-sized gold dredges come with built-in hookah-air systems. These attach to the same engine that powers the water pump. As demonstrated in the following video segment, air for breathing underwater is generated by an air compressor, passes down through an air line, and provides air to a diver through a regulator, similar to what is used by SCUBA divers: The

The

A cutter-head will just get bogged down (and damaged) in a normal

A cutter-head will just get bogged down (and damaged) in a normal  If you want to do serious excavations with a suction dredge, you must leave the opening of the suction-nozzle as large in diameter as possible, while still reducing it enough to eliminate un-necessary

If you want to do serious excavations with a suction dredge, you must leave the opening of the suction-nozzle as large in diameter as possible, while still reducing it enough to eliminate un-necessary

A gold-dredger has an advantage, in that he or she is able to float equipment where he or she wants it to go, sucking up gravel (sampling) from various strategic areas. This is much easier than having to carry equipment around and set it up in each new area, as is required in conventional mining.

A gold-dredger has an advantage, in that he or she is able to float equipment where he or she wants it to go, sucking up gravel (sampling) from various strategic areas. This is much easier than having to carry equipment around and set it up in each new area, as is required in conventional mining. In fact, most of the work associated with suction dredging involves the organization and movement of cobbles and (sometimes)

In fact, most of the work associated with suction dredging involves the organization and movement of cobbles and (sometimes)

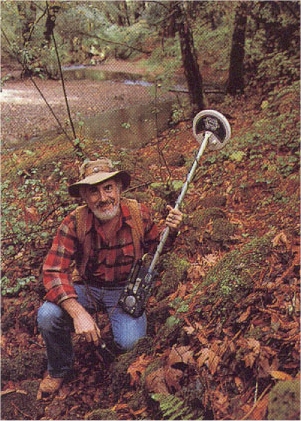

Some have said that the pen is mightier than the sword, and I am sure that on occasions this has truly been the case. Throughout the ages, man has used words to explain, convince and cajole his fellows about one thing or another. Advertising executives are no exception to the rule; and in their deft hands, a word can become downright dangerous or at least costly to some of us. I am, of course, speaking about the use of the language without explaining the meaning of the terms used.

Some have said that the pen is mightier than the sword, and I am sure that on occasions this has truly been the case. Throughout the ages, man has used words to explain, convince and cajole his fellows about one thing or another. Advertising executives are no exception to the rule; and in their deft hands, a word can become downright dangerous or at least costly to some of us. I am, of course, speaking about the use of the language without explaining the meaning of the terms used. But with the advent of meter identification on many detectors, the user was no-longer locked into searching in a discriminate mode with limited depth. He or she could finally search in an all-metal mode if desired and check the meter for probability of target identification. This is where the definition of terms is becoming important and what I have been leading up to. I have recently heard it said that this or that detector is better for prospecting because it doesn’t discriminate, and many a treasure hunter has set aside his or her perfectly good multipurpose unit and bought another unit just for prospecting. I am not suggesting that these new units are not worthy of the task; but in many instances, it was costly and unnecessary to buy two units. First of all, the original unit should be able to cancel the ground effectively; and secondly, the owner must learn the skills necessary to operate it in a prospecting environment. Every company makes such units, and all are capable of finding the elusive gold nugget. The meter should work independently of the all-metal audio signal. That is, you should be able to operate the detector in the all-metal mode and hear every target that the loop passes over. The meter should respond to these targets in some sort of predictable fashion.

But with the advent of meter identification on many detectors, the user was no-longer locked into searching in a discriminate mode with limited depth. He or she could finally search in an all-metal mode if desired and check the meter for probability of target identification. This is where the definition of terms is becoming important and what I have been leading up to. I have recently heard it said that this or that detector is better for prospecting because it doesn’t discriminate, and many a treasure hunter has set aside his or her perfectly good multipurpose unit and bought another unit just for prospecting. I am not suggesting that these new units are not worthy of the task; but in many instances, it was costly and unnecessary to buy two units. First of all, the original unit should be able to cancel the ground effectively; and secondly, the owner must learn the skills necessary to operate it in a prospecting environment. Every company makes such units, and all are capable of finding the elusive gold nugget. The meter should work independently of the all-metal audio signal. That is, you should be able to operate the detector in the all-metal mode and hear every target that the loop passes over. The meter should respond to these targets in some sort of predictable fashion.

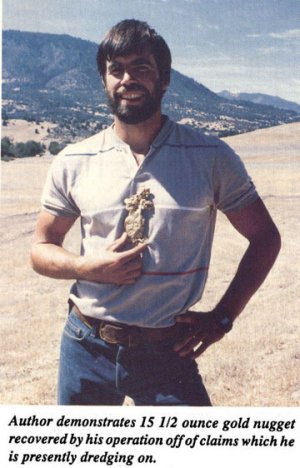

Several years ago, I decided to devote my time entirely to nugget hunting in

Several years ago, I decided to devote my time entirely to nugget hunting in  1) Seek out friends or other qualified individuals who can answer questions and show you how to use metal detectors designed for gold nugget hunting. Nugget detecting is a specialized field in itself.

1) Seek out friends or other qualified individuals who can answer questions and show you how to use metal detectors designed for gold nugget hunting. Nugget detecting is a specialized field in itself.